1. Machine Size and Diameter. 2. Gauge and Needle Selection. 3. Jacquard System. 4. Yarn Feeder Options. 5. Machine Speed and Efficiency. 6. Maintenance and Service. 7. Cost and Return on Investment. 8. User-Friendliness and Training. Conclusion....

1. Apparel Industry. 2. Home Textiles. 3. Automotive Industry. 4. Sports and Activewear. 5. Medical Textiles. 6. Technical Textiles. 7. Fashion Accessories. 8. Research and Development. Conclusion....

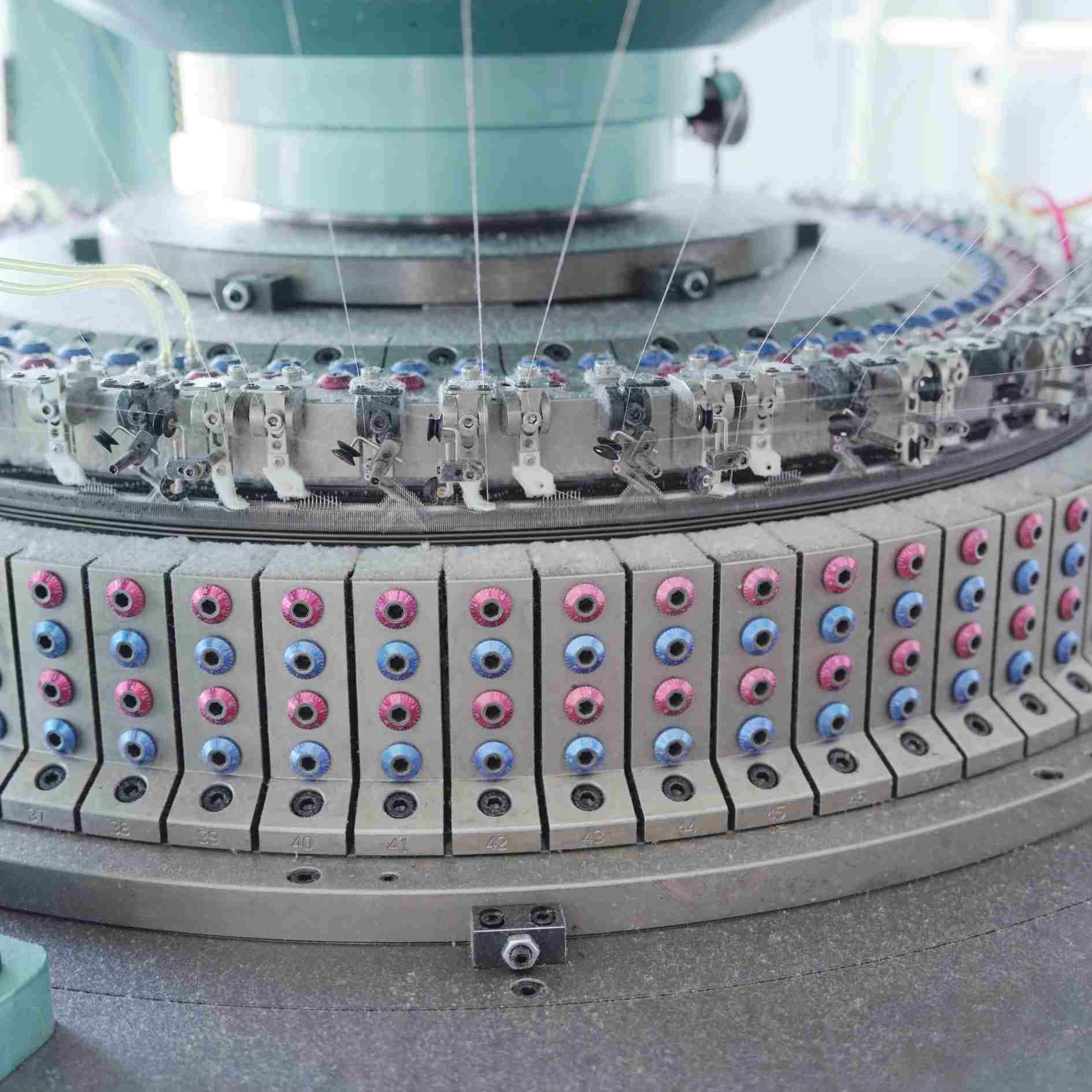

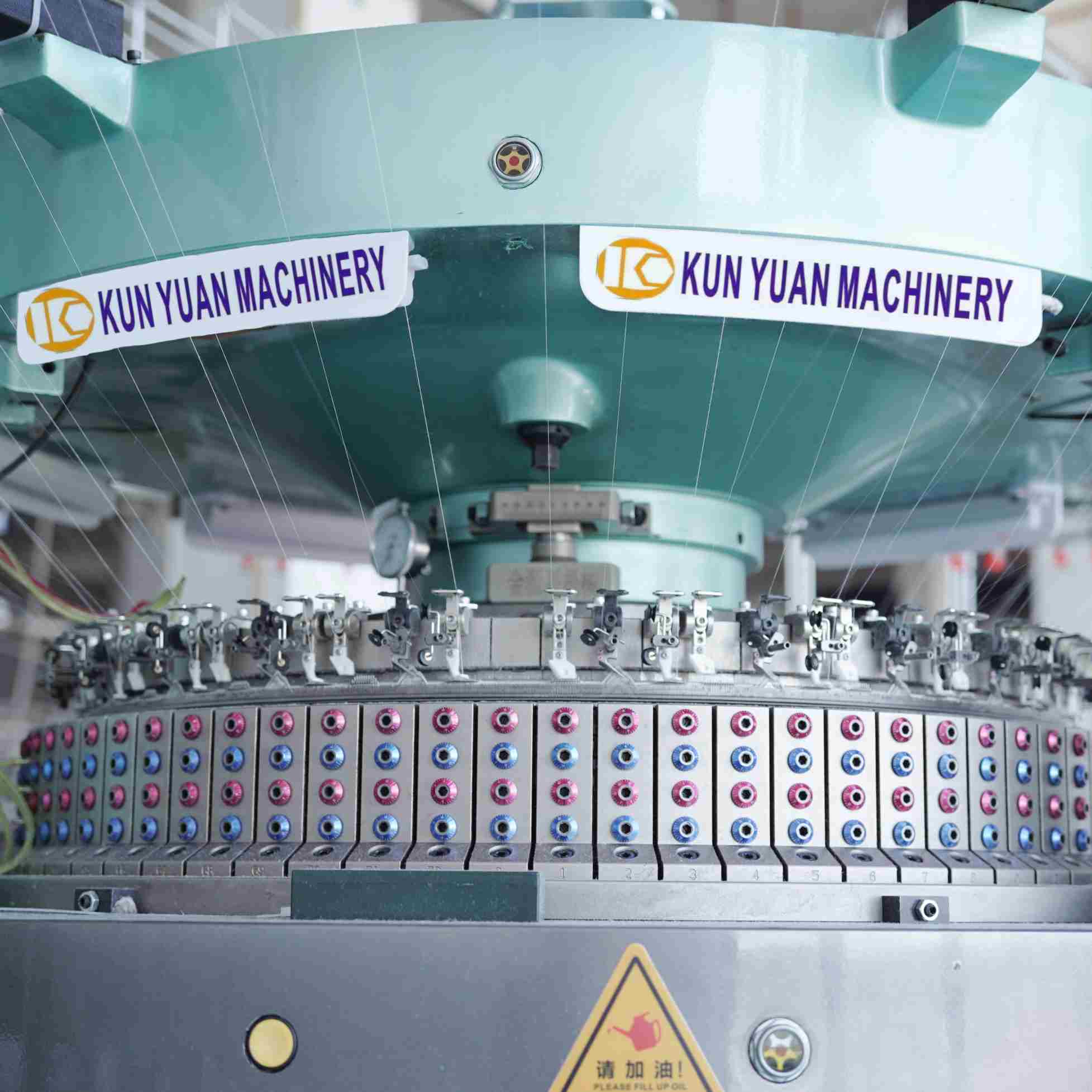

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot ...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...