Improved Efficiency. Versatility in Design. Enhanced Comfort and Fit. Cost Efficiency. Increased Durability. Reduced Environmental Impact. Greater Customization. Improved Profitability. Conclusion....

Advantages of Body Size Circular Knitting Machine. High Production Efficiency. Versatility in Fabric Production. Reduced Material Wastage. Quality Control and Consistency. Advanced Technological Features. Energy Efficiency and Sustainability. Production Process of Body Size Circular Knitting Machine. Conclusion....

Early Manual Circular Knitting Machines. Introduction of Semi-Automatic Machines. Transition to Fully Automatic Machines. Incorporation of Computerized Systems. Advancements in Body Size and Speed. Integration of Sustainable Practices. Impact on Textile Industry. Conclusion....

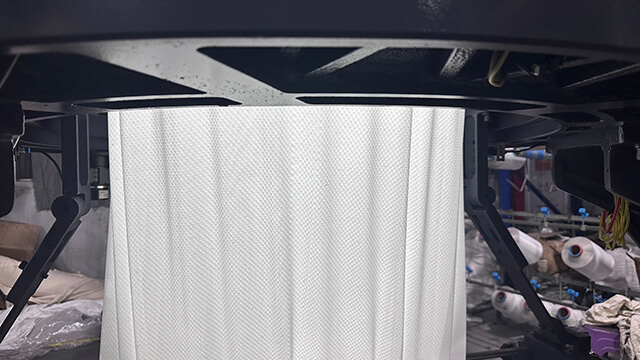

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

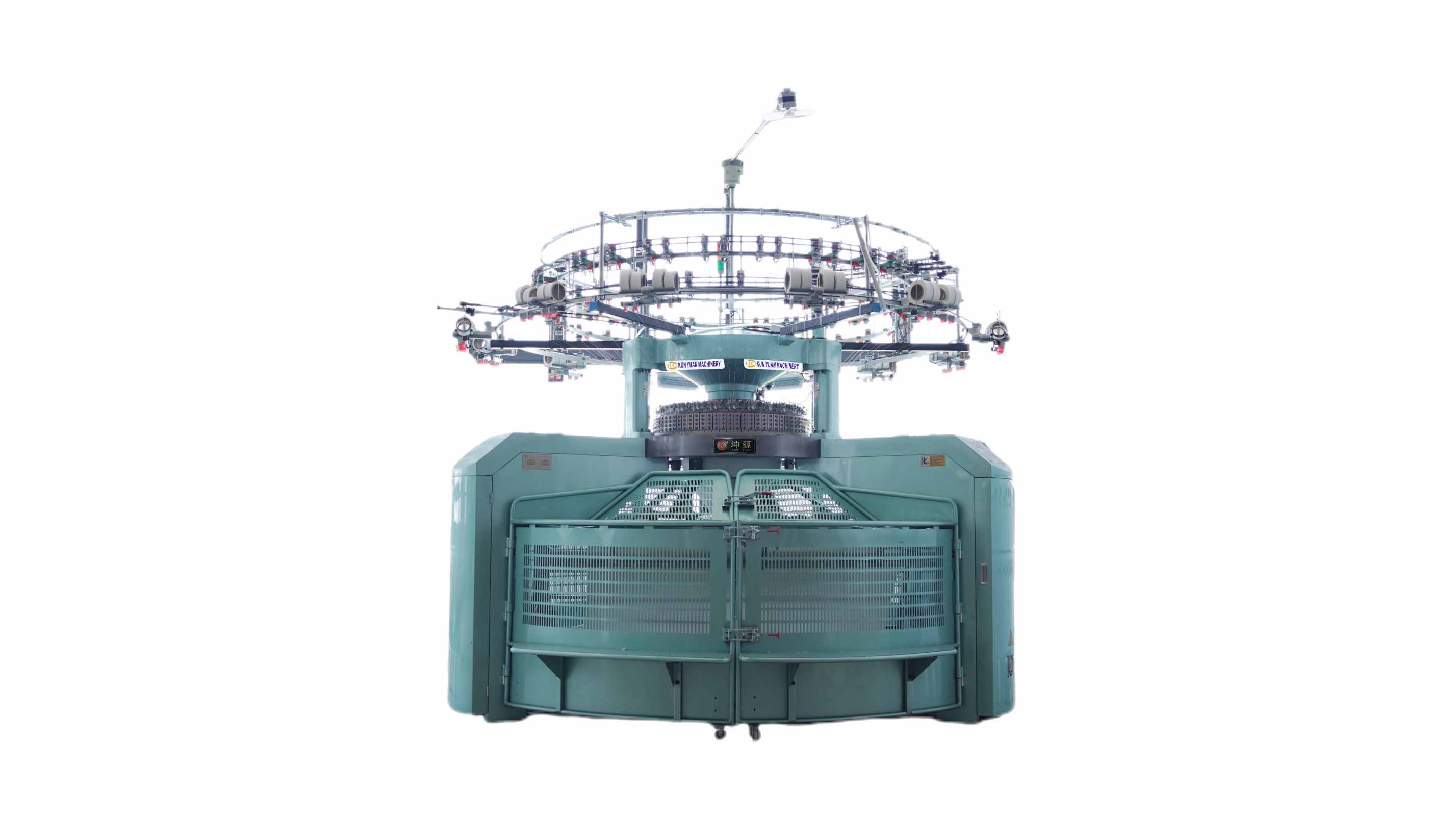

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

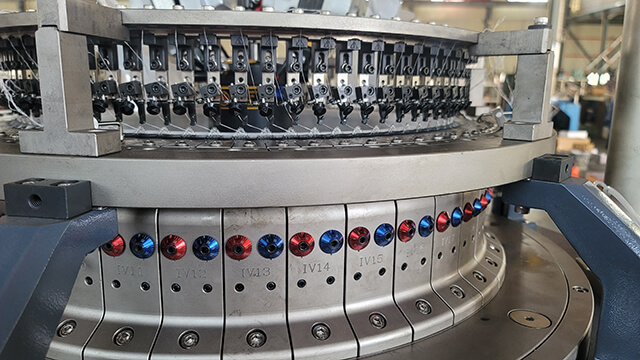

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...