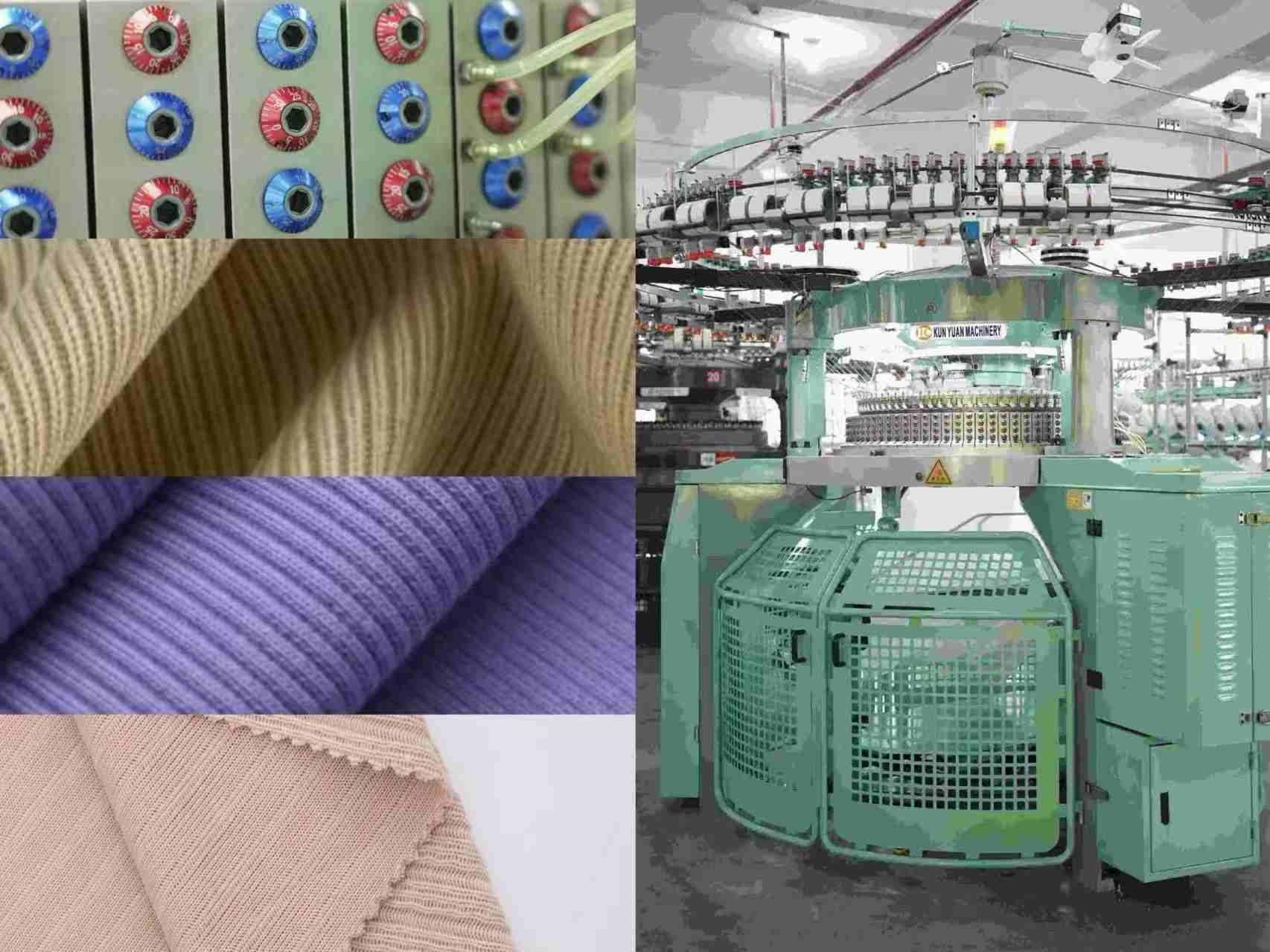

1. Apparel Manufacturing. 2. Home Textiles. 3. Technical Textiles. 4. Sportswear. 5. Medical Textiles. 6. Automotive Industry. 7. Filtration and Separation. 8. Fashion Design. Conclusion....

1. Machine Type. 2. Needle Count. 3. Machine Size. 4. Durability and Maintenance. 5. Speed and Production Capacity. 6. User-Friendliness and Automation. 7. Power Consumption. 8. Price and Warranty. Conclusion....

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

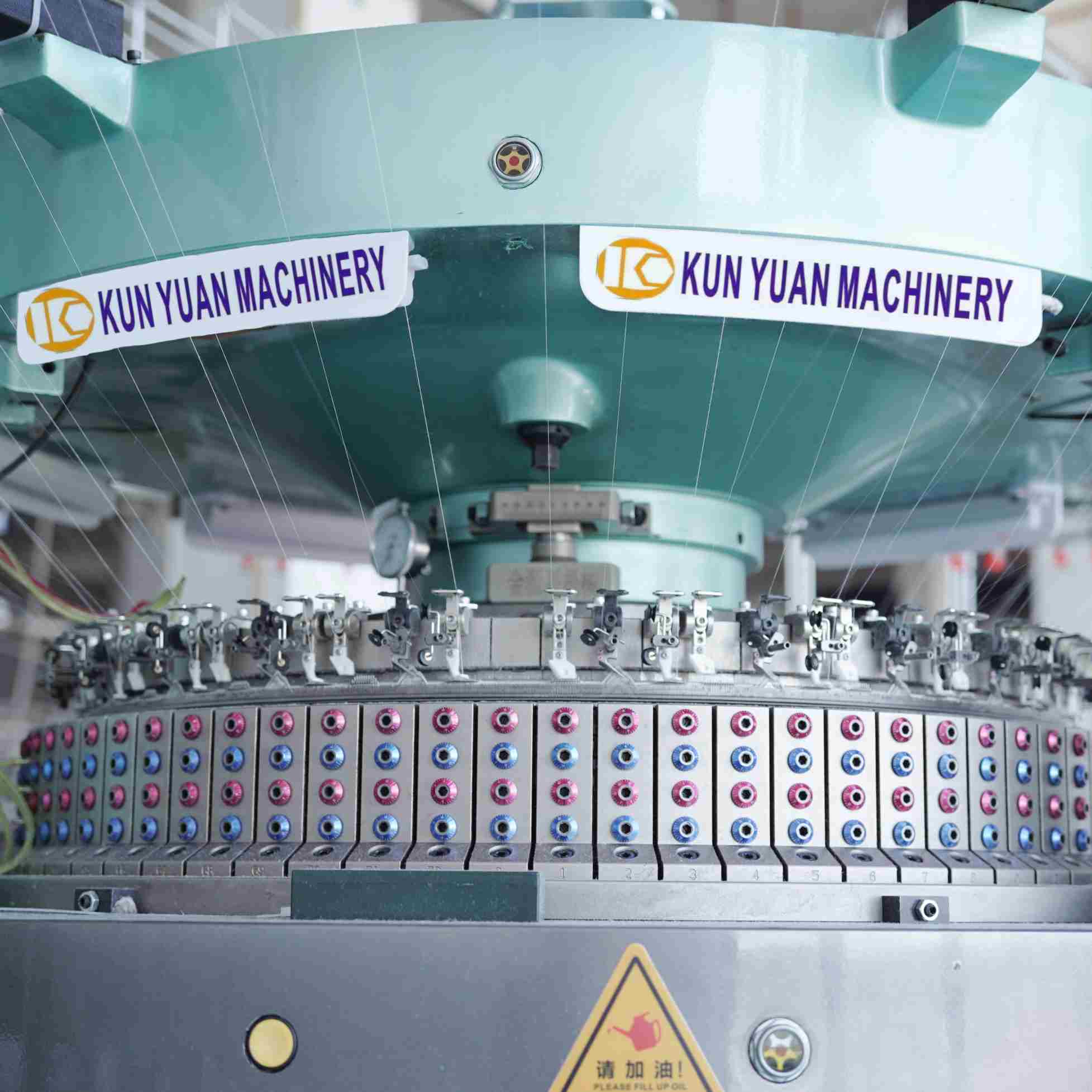

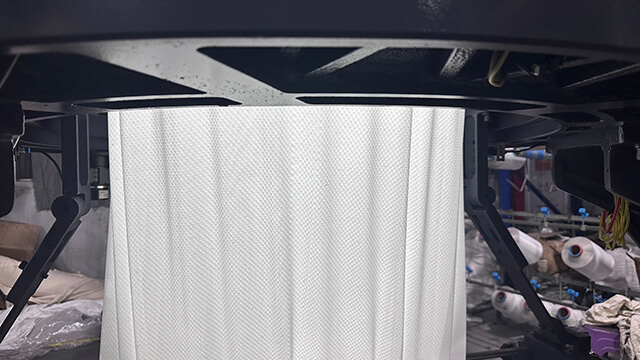

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elasti...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...