Introduction. 1. Enhanced Design Flexibility. 2. Efficient Production Process. 3. Seamless Comfort and Fit. 4. Customization and Personalization. 5. Sustainable Production. 6. Innovation in Shape and Structure. 7. Integration with Technology. 8. Expanding Market Opportunities. Conclusion....

The Origins of Circular Knitting. Early Circular Knitting Machines. The Introduction of Automated Circular Knitting Machines. Advancements in Technology. Specialized Circular Knitting Machines for Hats. Incorporation of Sustainable Practices. Integration of Smart Features. Future Prospects and Innovations. In Conclusion....

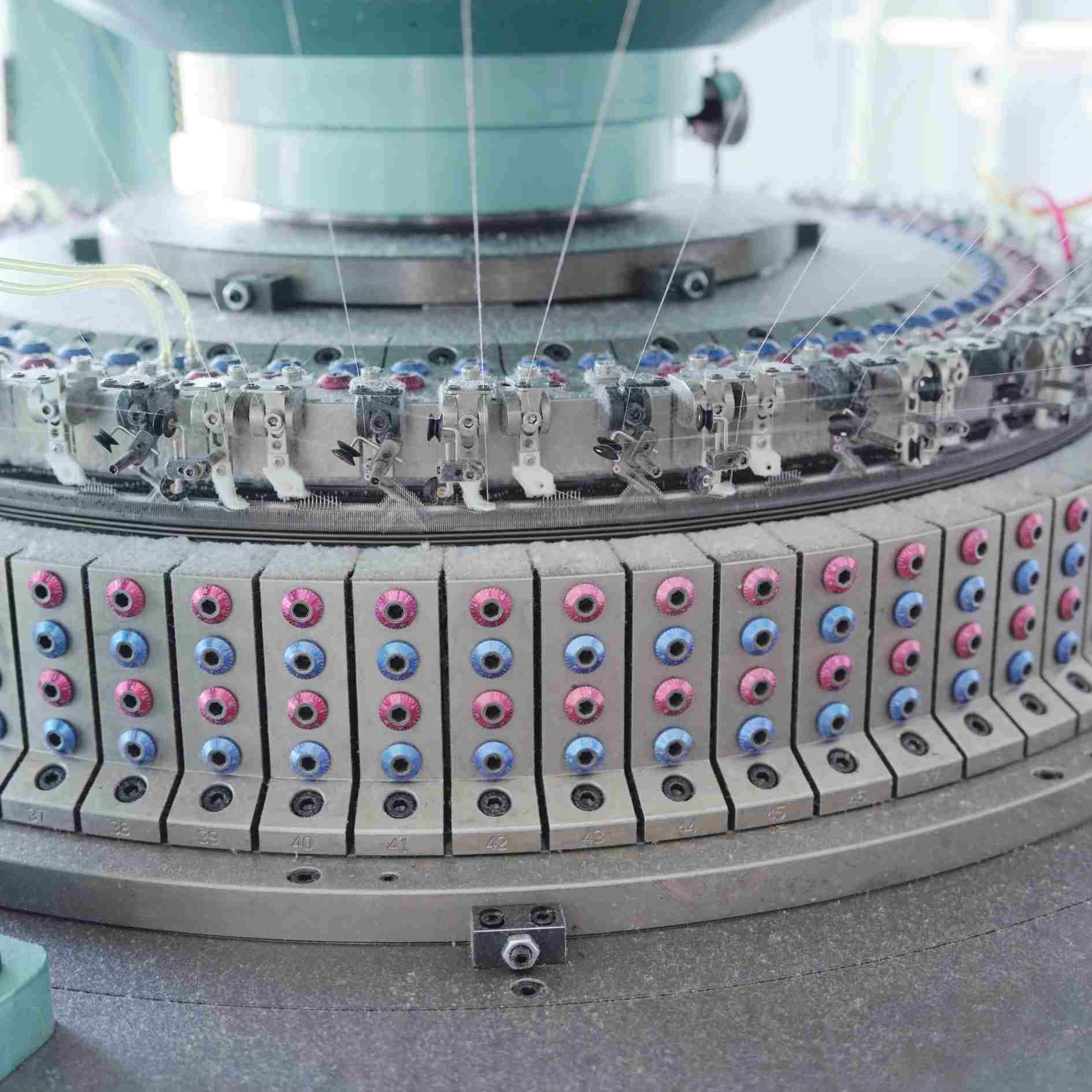

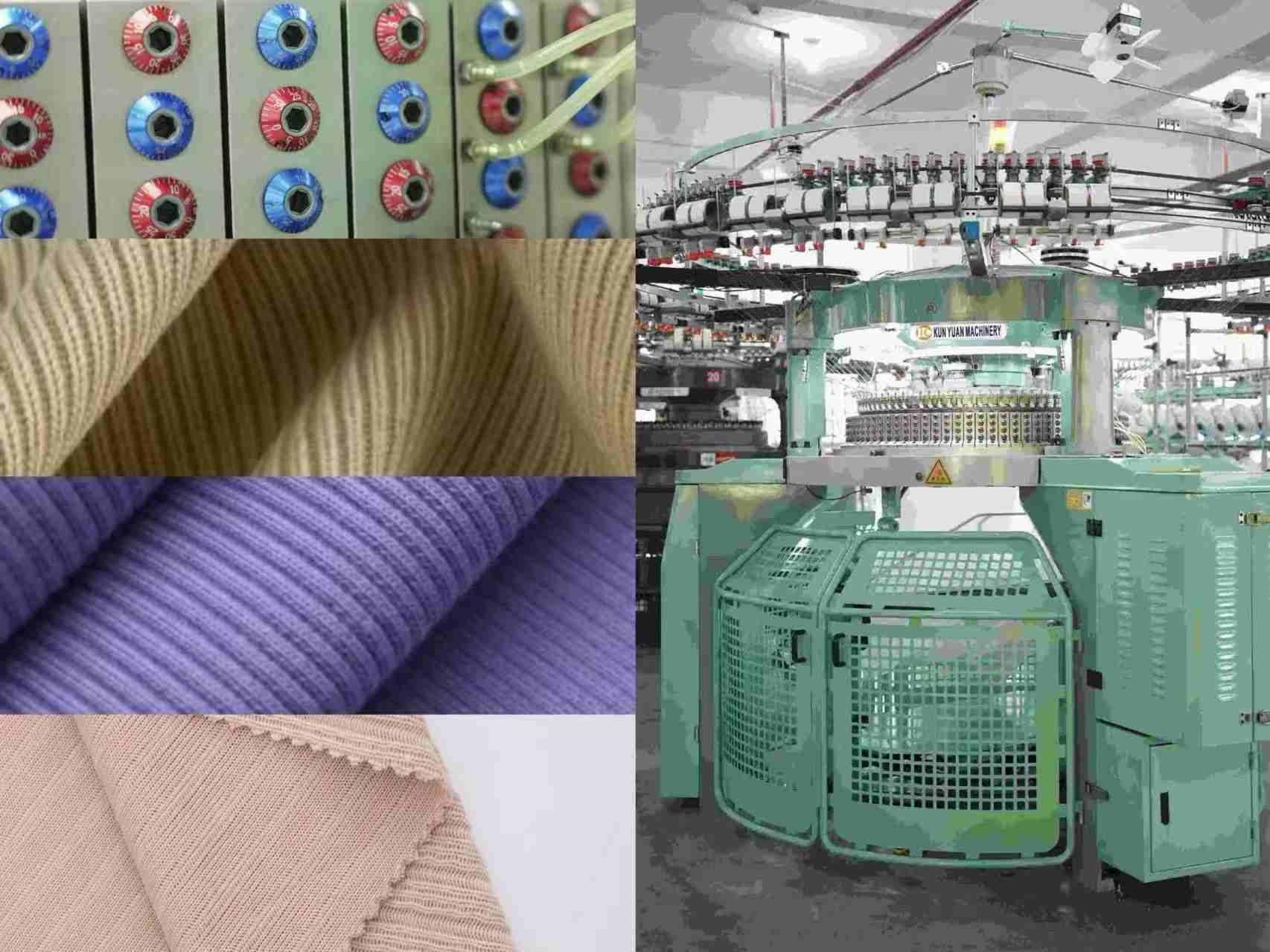

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elasti...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...

The 36-Inch 32G 108F Double-Sided Knitting Machine is a state-of-the-art textile machine designed for high-quality, double-sided knitted fabric production. This machine is ideal for p...