1. The Birth of Circular Knitting Machines. 2. Technological Advancements: Cast-Iron to High-Strength Alloys. 3. On-the-Fly Pattern Changes. 4. Automation and Digitization. 5. Versatility: From T-Shirts to Technical Textiles. 6. Energy Efficiency and Sustainability. 7. Integration of Industry 4.0 Technologies. 8. Future Prospect...

Advanced Technology. Versatile Production Capabilities. Efficient Output Efficiency. Energy and Resource Savings. Intuitive Operation and Maintenance. Quality Control and Consistency. Adaptability to Different Yarns and Fibers. Integration with Industry 4.0....

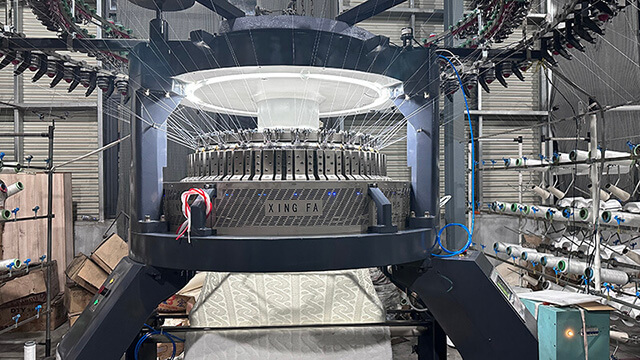

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for pr...

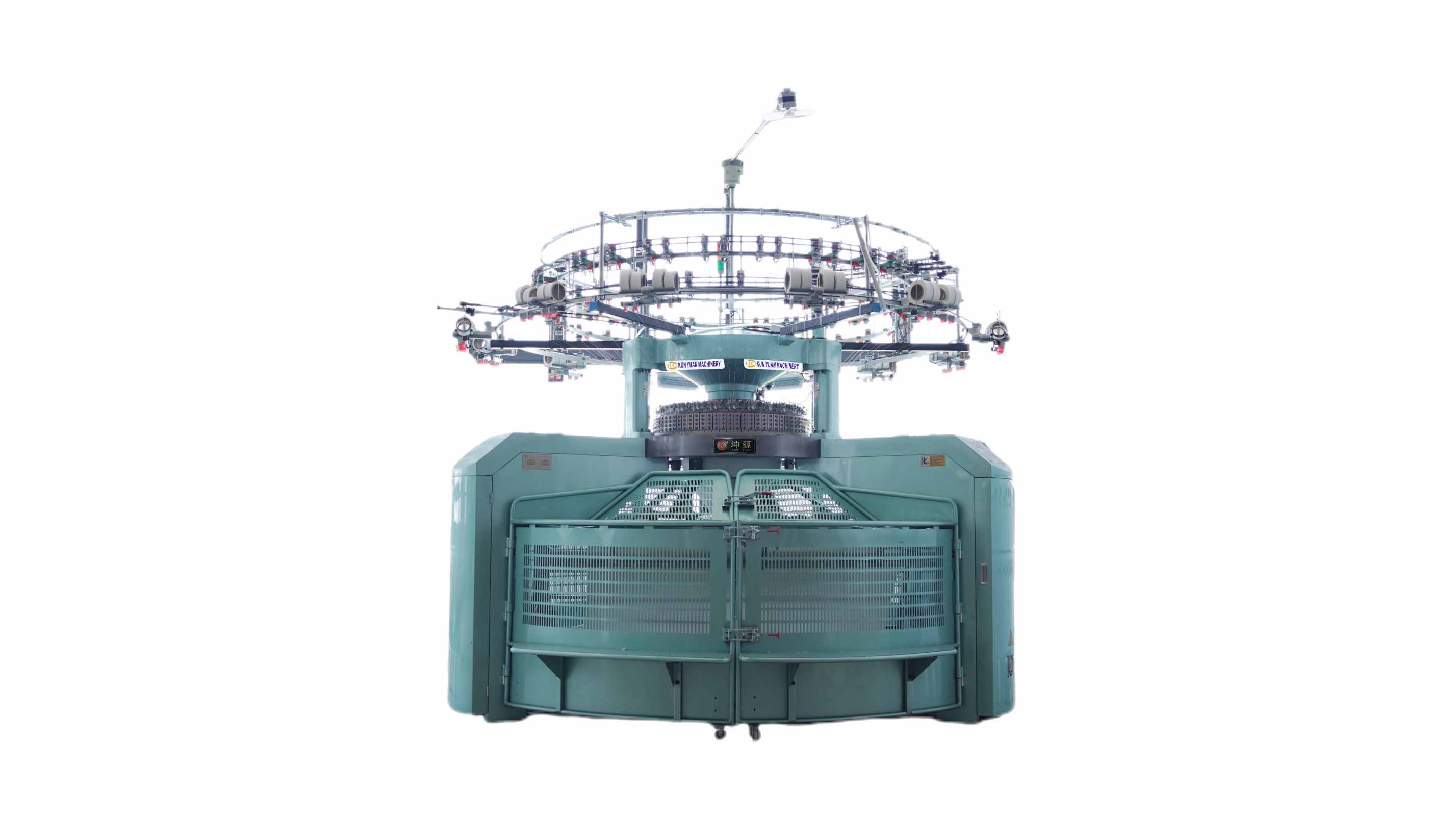

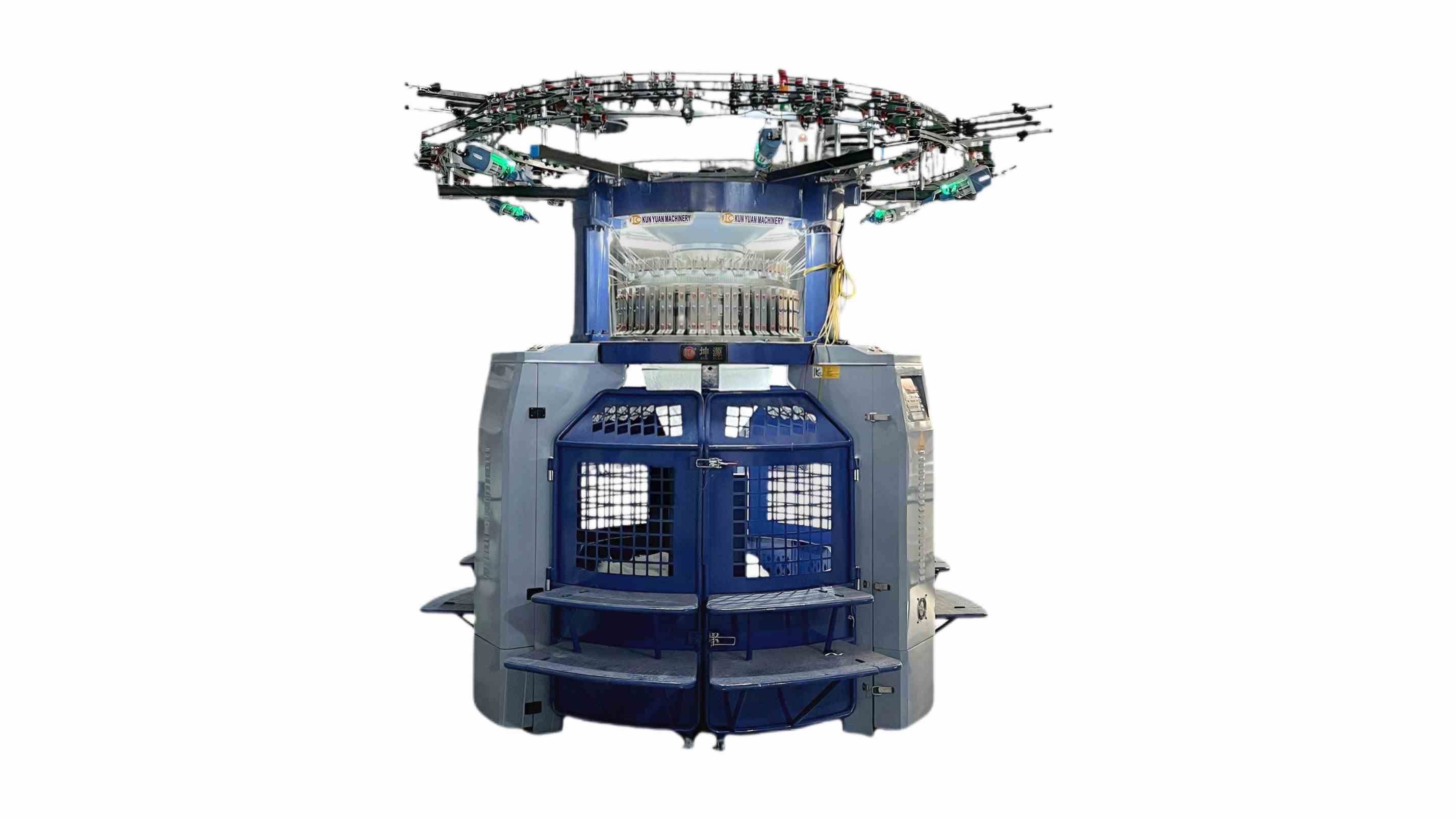

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot ...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...