1. The Basics of Motorized Knitting Machines. 2. Needle Selection and Tension. 3. Yarn Feeding and Control. 4. Stitch Formation and Transfer. 5. Pattern Programming and Jacquard Knitting. 6. Speed and Productivity. 7. Quality Control and Troubleshooting. 8. Advancements and Future Possibilities. Conclusion....

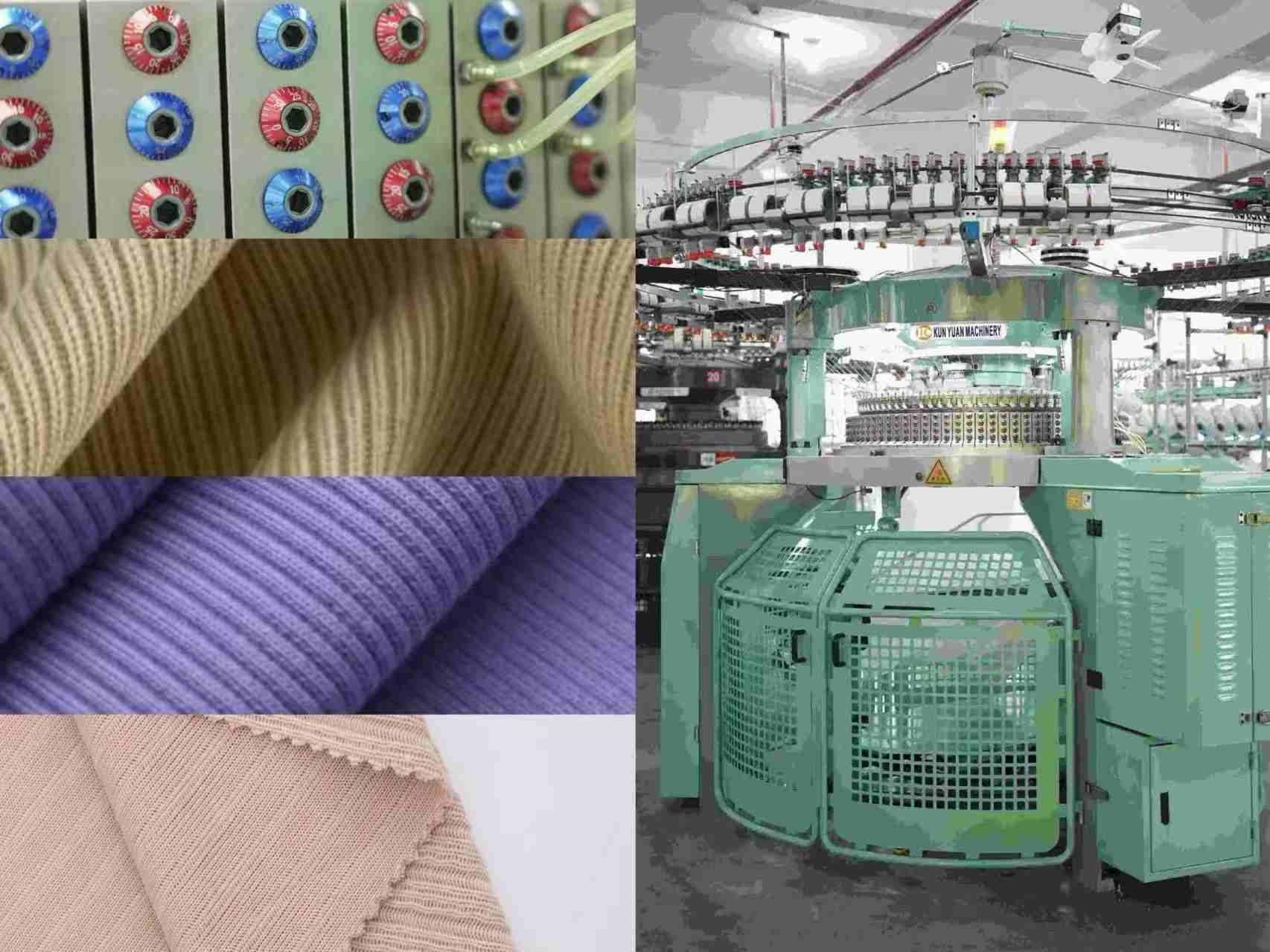

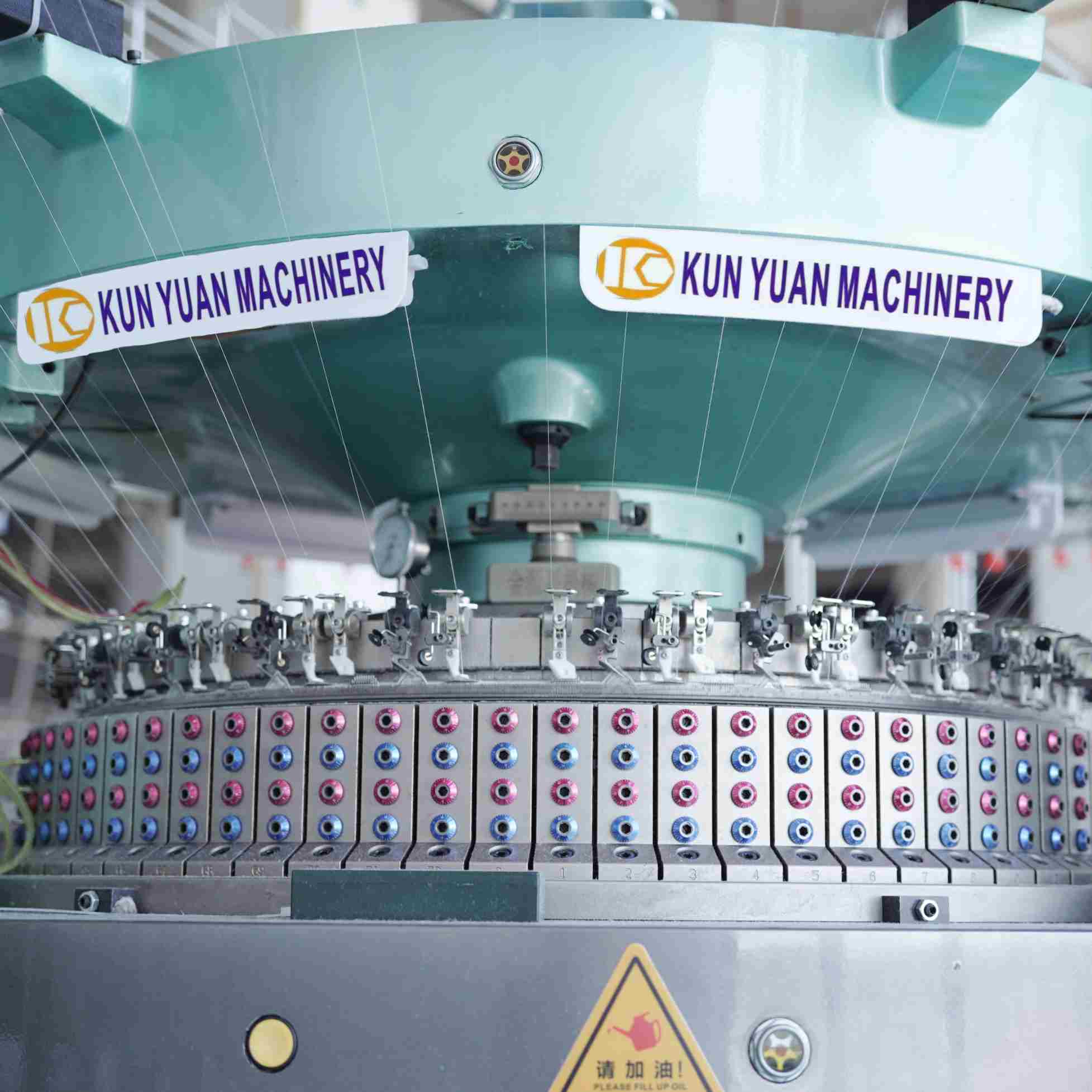

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elasti...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...