1. Computerized Controls. 2. Multi-Feeder Systems. 3. Automatic Yarn Changers. 4. Seamless Knitting. 5. High-Speed Performance. 6. Fabric Quality Monitoring. 7. Energy Efficiency. 8. Customization and Flexibility. Conclusion....

Introduction. 1. Understanding the Machine. 2. Preparing the Site. 3. Unboxing and Assembly. 4. Electrical and Mechanical Connections. 5. Calibrating and Testing. 6. Training and Familiarization. 7. Integration with Production Workflow. 8. Maintenance and Support. Conclusion....

1. Increased Efficiency. 2. Precision and Consistency. 3. Versatility in Design. 4. Time and Cost Savings. 5. Enhanced Productivity. 6. Improved Quality Control. 7. Sustainable and Environmentally Friendly. 8. Innovation and Adaptability. Conclusion....

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for pr...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

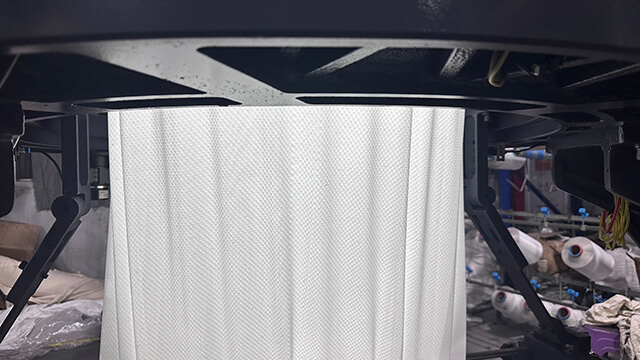

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...