Introduction. 1. Unpacking the Machine. 2. Placement and Leveling. 3. Power Supply. 4. Installing Needles and Yarn Feeders. 5. Lubrication. 6. Testing and Calibration. 7. Safety Measures. Conclusion....

1. Production of Basic Knitted Fabrics. 2. Seamless Garment Production. 3. Elastic and Stretch Fabrics. 4. Textured and Patterned Fabrics. 5. Jacquard and Intarsia Knitting. 6. Sample and Prototyping. 7. Recycling and Upcycling Projects. 8. Knitting Education and Training. Conclusion:....

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

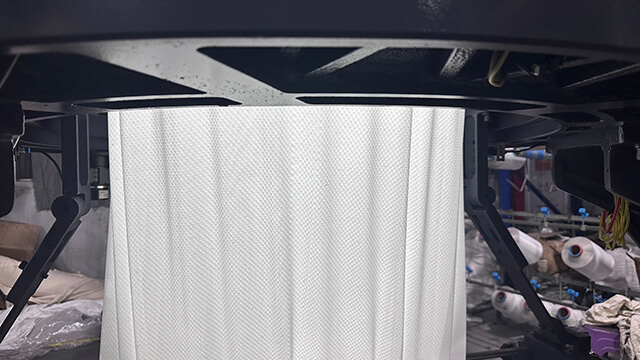

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

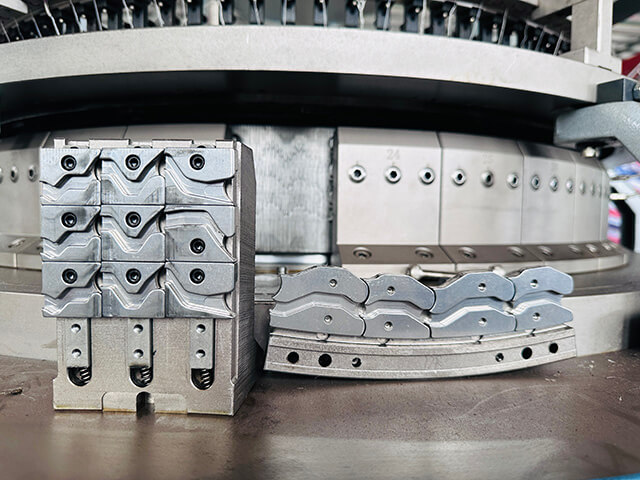

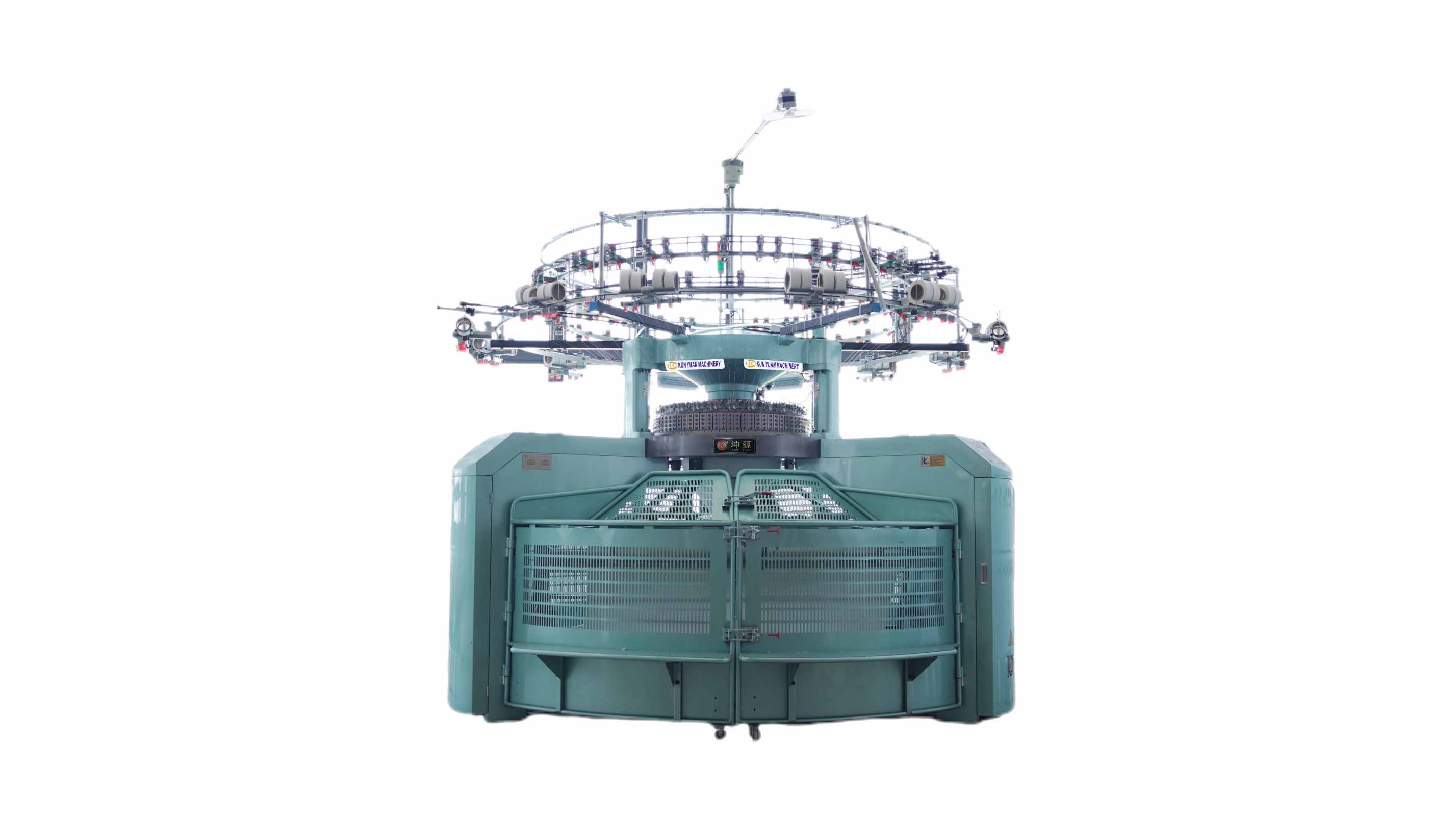

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and effi...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...