1. Determine Your Requirements. 2. Research Different Brands and Models. 3. Consider the Machine's Features. 4. Assess the Machine's Ease of Use. 5. Evaluate the Machine's Durability and Maintenance. 6. Set a Realistic Budget. 7. Test the Machine if Possible. 8. Seek Expert Advice. Conclusion....

1. Apparel Industry. 2. Home Textiles. 3. Automotive Industry. 4. Sports and Outdoor Equipment. 5. Medical and Healthcare. 6. Hospitality Industry. 7. Cleaning and Janitorial Services. 8. Industrial Applications. Conclusion....

1. Cleaning the Machine. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Check the Belts and Pulleys. 6. Regular Calibration. 7. Electrical Safety. 8. Record Keeping. Conclusion....

Introduction. 1. Unboxing and Inspection. 2. Choosing the Right Location. 3. Assembling the Machine. 4. Connecting Power and Yarn. 5. Familiarizing Yourself with the Controls. 6. Testing and Troubleshooting. 7. Maintenance and Cleaning. 8. Expanding Your Skills. Conclusion....

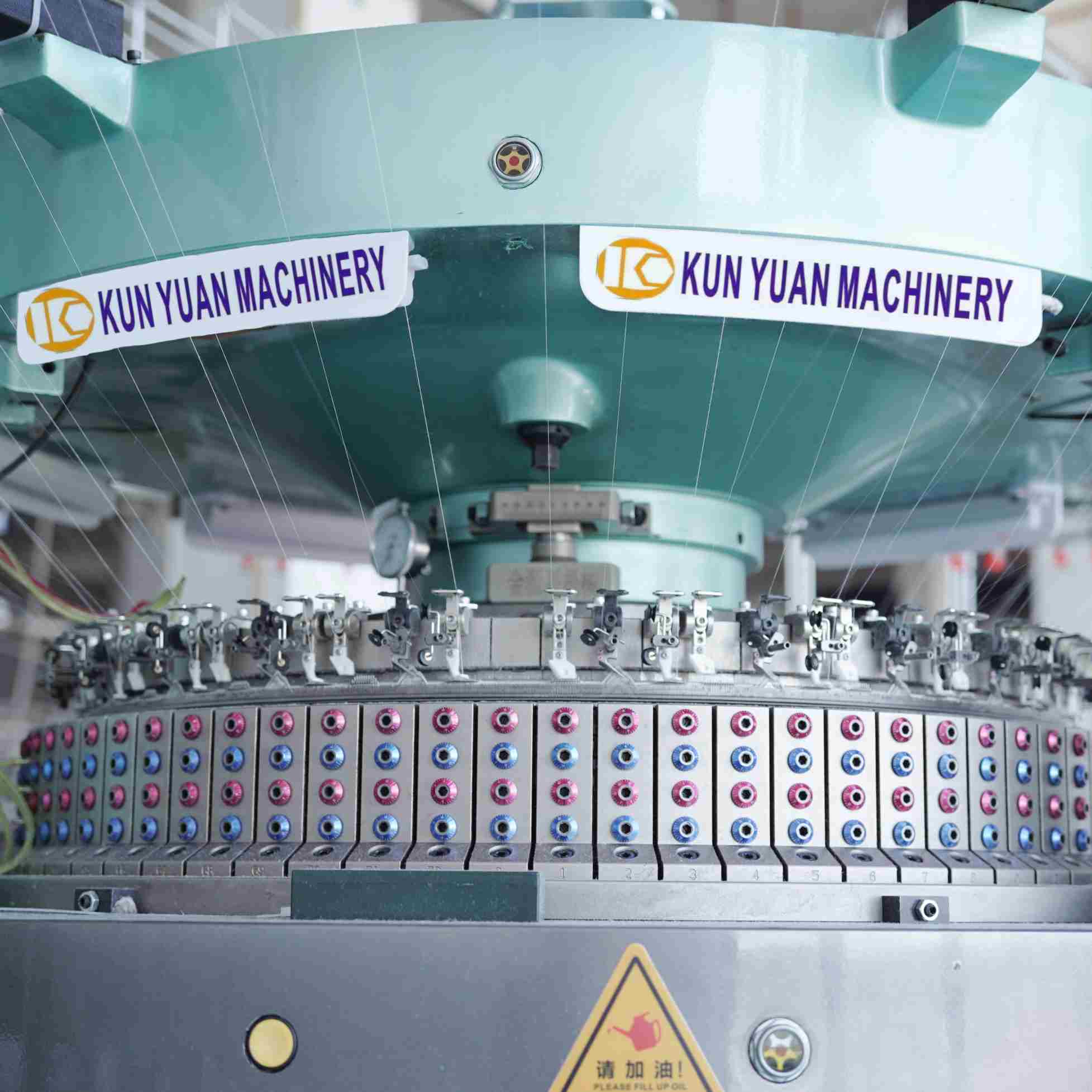

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for pr...

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

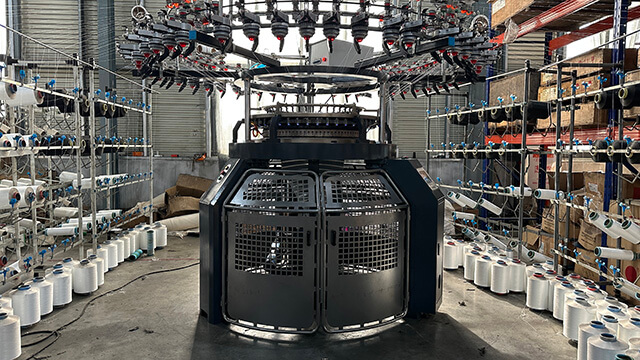

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...