Introduction. 1. Determine Your Knitting Goals. 2. Consider Machine Type. 3. Evaluate Knitting Bed Size. 4. Check Needle Compatibility. 5. Research Machine Features. 6. Consider Portability. 7. Read Reviews and Seek Recommendations. 8. Set a Budget. Conclusion....

1. Determine Your Production Requirements. 2. Research Different Models. 3. Consider the Machine Size. 4. Examine the Machine Features. 5. Evaluate the Machine's Durability. 6. Assess the User-Friendliness. 7. Compare Prices. 8. Seek Recommendations. Conclusion....

1. Knitting Capacity. 2. Needle Gauge. 3. Rib Structure. 4. Machine Versatility. 5. Machine Durability. 6. Cost. 7. Technical Support and Training. 8. User Reviews and Recommendations....

1. Determine your production needs. 2. Research different brands and models. 3. Consider machine specifications. 4. Evaluate ease of use. 5. Assess the machine's versatility. 6. Consider the machine's maintenance requirements. 7. Calculate the total cost of ownership. 8. Seek recommendations and reviews. Conclusion. ...

Introduction. 1. Determine Your Skill Level. 2. Research Available Circles. 3. Visit Potential Circles. 4. Consider Location and Accessibility. 5. Evaluate Teaching and Learning Opportunities. 6. Assess the Community and Social Aspect. 7. Seek Recommendations and Feedback. 8. Trust Your Gut Feeling. Conclusion. ...

1. Determine Your Production Requirements. 2. Evaluate Machine Features. 3. Consider Machine Size and Configuration. 4. Quality and Reliability. 5. Cost and Return on Investment. 6. Technical Support and Training. 7. Consider Future Expansion. 8. Seek Expert Advice. Conclusion....

1. Consider the Size. 2. Check the Gauge. 3. Evaluate the Material. 4. Look for Versatility. 5. Consider the Price. 6. Read Reviews. 7. Test the Machine. 8. Seek Recommendations. Conclusion....

Introduction. 1. Consider Your Project Requirements. 2. Research Different Brands and Models. 3. Evaluate Machine Features. 4. Consider Machine Size and Portability. 5. Examine Machine Durability. 6. Compare Prices and Warranty. 7. Seek Professional Advice. 8. Test the Machine Before Purchase. Conclusion....

1. Determine Your Needs. 2. Research Brands and Models. 3. Consider Machine Features. 4. Assess Durability and Reliability. 5. Evaluate Price and Value. 6. Test the Machine. 7. Compare Warranty and Support. 8. Seek Recommendations. Conclusion....

1. Fashion-forward Designs. 2. Customization and Personalization. 3. Seamless Construction. 4. Sustainable Manufacturing. 5. Versatility of Fabrics. 6. Enhanced Comfort and Durability. 7. Automation and Efficiency. 8. Cost-effectiveness. Conclusion....

1. Apparel Industry. 2. Home Textiles. 3. Automotive Industry. 4. Sports and Outdoor Equipment. 5. Medical and Healthcare. 6. Hospitality Industry. 7. Cleaning and Janitorial Services. 8. Industrial Applications. Conclusion....

1. Increased Production Efficiency. 2. Vast Design Possibilities. 3. Improved Fabric Quality. 4. Eco-Friendly Manufacturing. 5. Customization and Personalization. 6. Cost-Effective Production. 7. Versatile Applications. 8. Constant Advancements and Innovations. Conclusion....

1. Garment Production. 2. Accessory Design. 3. Home Decor. 4. Artistic Creations. 5. Fashion Design. 6. Educational Tool. 7. Therapeutic Benefits. 8. Small Business Opportunities. Conclusion....

Introduction. 1. Fashion Industry. 2. Sports Apparel. 3. Home Textiles. 4. Medical Textiles. 5. Automotive Industry. 6. Technical Textiles. 7. Footwear Industry. 8. Design Prototyping. Conclusion....

1. Fashion Industry. 2. Sportswear Manufacturing. 3. Medical Textiles. 4. Home Textiles. 5. Automotive Industry. 6. Technical Textiles. 7. Footwear Industry. 8. Sustainable Fashion. Conclusion....

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and effi...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitti...

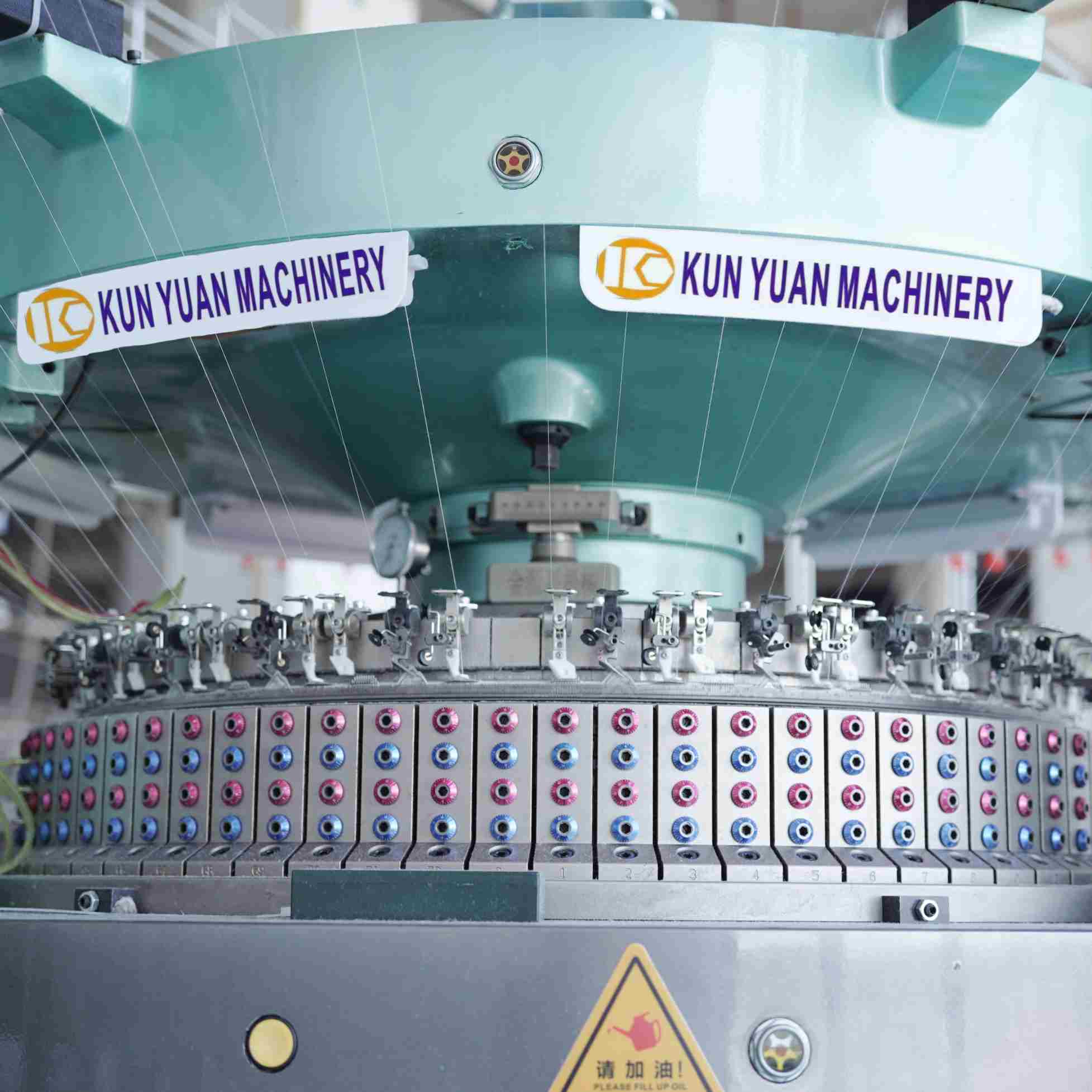

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...