Early Origins. Mechanization and Industrialization. Computerization and Automation. Innovations in Materials. Sustainability and Environmental Considerations. Integration of Smart Features. Future Prospects and Advancements. Conclusion....

Advantages of High Pile Knitting Machine. 2. Efficiency and Speed. 3. Enhanced Texture and Appearance. 4. Customization and Innovation. 5. Environmental Sustainability. 6. Consistency and Quality. 7. Cost-Effectiveness. 8. Automation and Control. Production Process of High Pile Knitting Machine. Yarn Feeding. Knitting. Pile Form...

Advantages of Double Circular Knitting Machine. High Production Efficiency. Economical Use of Yarn. Flexible Fabric Design. Advanced Technology Integration. Energy Efficiency. Automation and Labor Savings. Production Process of Double Circular Knitting Machine. Conclusion....

Advantages of Circular Pile Knitting Machine. 2. Versatile Fabric Options. 3. Superior Fabric Quality. 4. Reduced Waste and Material Costs. 5. Customization Capabilities. 6. Energy Efficiency. Production Process of Circular Pile Knitting Machine. 8. Loop Formation and Pile Fabric Creation. Conclusion....

1. Versatility in Design. 2. Enhanced Comfort and Fit. 3. Reduced Production Time. 4. Cost-Effective Manufacturing. 5. Seamless Integration of Features. 6. Environmentally Friendly Production. 7. Diverse Yarn Compatibility. 8. Quality Control and Consistency. Conclusion....

1. Read the Care Instructions. 2. Hand Wash or Use a Delicate Cycle. 3. Use Cold Water. 4. Dry Flat. 5. Avoid Direct Sunlight and Heat. 6. Never Use an Iron. 7. Store Properly. 8. Gently Remove Pills. Conclusion....

Advantages of Circular Knitting Machine Needles. Durability and Precision. Specialized Needle Designs. Efficient Yarn Handling. Production Process of Circular Knitting Machine Needles. Needle Manufacturing Techniques. Surface Coating and Finishing. End-to-End Inspection and Testing. Conclusion....

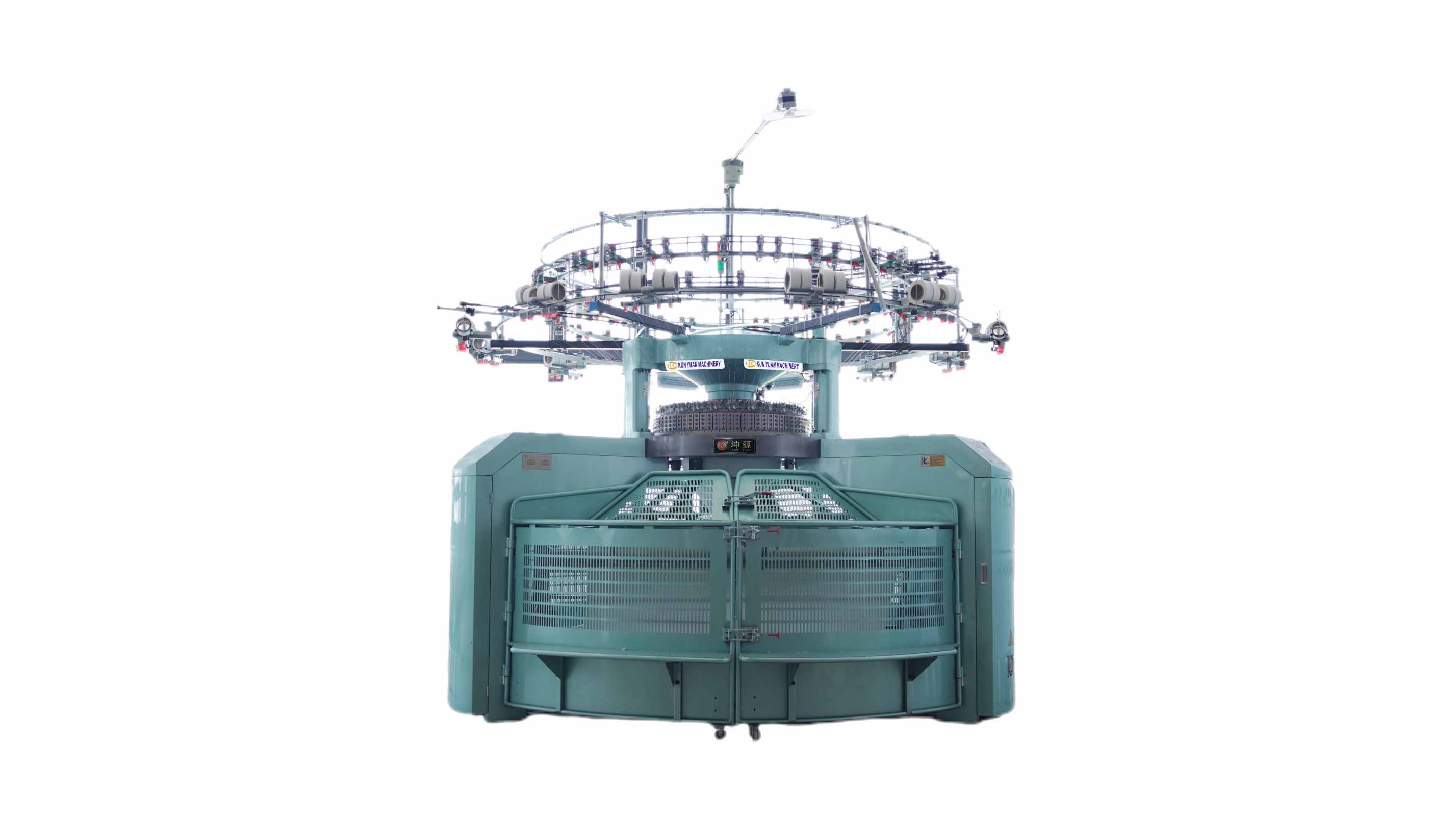

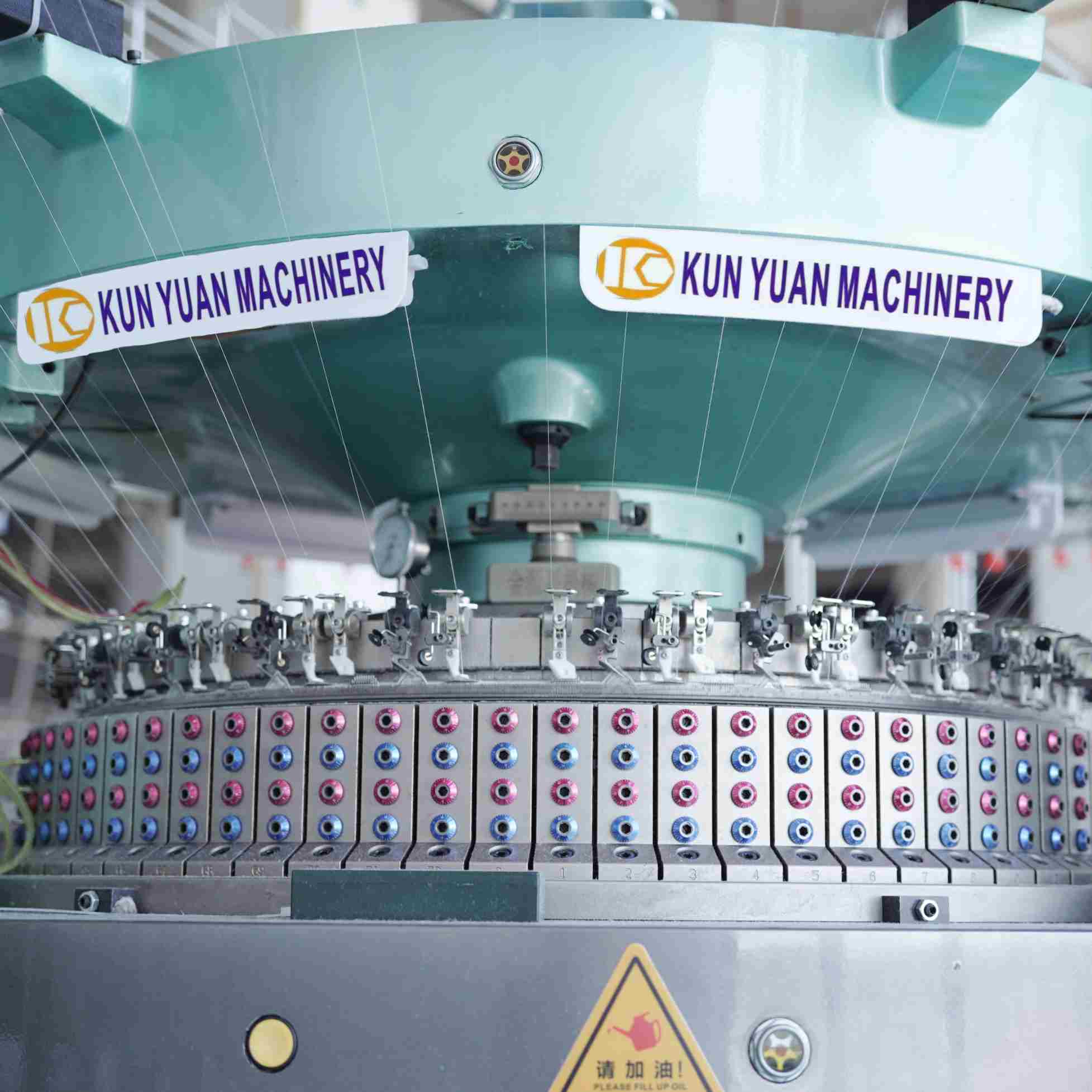

Advantages of Circular Knitting Machine. High Production Efficiency. Versatility and Flexibility. Cost-Effectiveness. Quality and Consistency. Production Process of Circular Knitting Machine Metal. Machining and Fabrication. Assembly and Quality Control. Final Testing and Performance Validation. Conclusion....

1. Gather Your Materials. 2. Read the Instruction Manual. 3. Assemble the Machine. 4. Prepare the Yarn. 5. Set Up the Machine. 6. Thread the Yarn. 7. Practice with Scrap Yarn. 8. Experiment and Have Fun. Summary....

Introduction. 1. Cleaning and Dusting. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Check for Wear and Tear. 6. Electrical Connections. 7. Regular Servicing. Conclusion....

Advantage 1: High Production Speed. Advantage 2: Customization Capabilities. Advantage 3: Reduced Labor Costs. Advantage 4: Consistent Quality. Advantage 5: Material Utilization. Advantage 6: Versatility in Yarn Selection. Advantage 7: Minimal Maintenance Requirements. Advantage 8: Scalability and Automation Integration. Conclus...

Advantages of Body Size Circular Knitting Machine. High Production Efficiency. Versatility in Fabric Production. Reduced Material Wastage. Quality Control and Consistency. Advanced Technological Features. Energy Efficiency and Sustainability. Production Process of Body Size Circular Knitting Machine. Conclusion....

Introduction. Advantages of Automatic Circular Knitting Machine. Production Process of Automatic Circular Knitting Machine. Conclusion....

Early Origins and Conceptualization. Emergence of Computerized Control Systems. Advancements in Yarn Feeding Mechanisms. Integration of Seamless Fabric Inspection. Incorporation of Multi-Gauge Knitting Capabilities. Transition to Energy-Efficient Design. Introduction of Industry 4.0 Technologies. Conclusion: Evolution and Future...

Increased Productivity. Versatile Design Options. Cost-Effective Production. Enhanced Quality and Consistency. Adaptability to Various Yarns. Integrated Technology and Automation. Energy Efficiency. Innovative Production Process. Conclusion....

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitti...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...