1. Fashion Apparel. 2. Active and Performance Wear. 3. Medical Textiles. 4. Automotive Industry. 5. Home Textiles. 6. Industrial and Technical Textiles. 7. Footwear Industry. 8. Sustainable Textiles. Conclusion....

1. Regular Cleaning. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Electronic Component Inspection. 6. Belt and Chain Maintenance. 7. Safety Precautions. 8. Professional Servicing. Conclusion....

Introduction. 1. Consider the Knitting Needle Type. 2. Gauge Compatibility. 3. Machine Size and Portability. 4. Automation and Features. 5. Durability and Longevity. 6. Price Range. 7. User Reviews and Recommendations. Conclusion....

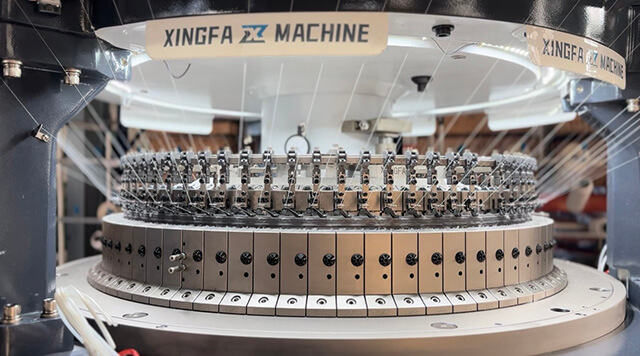

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

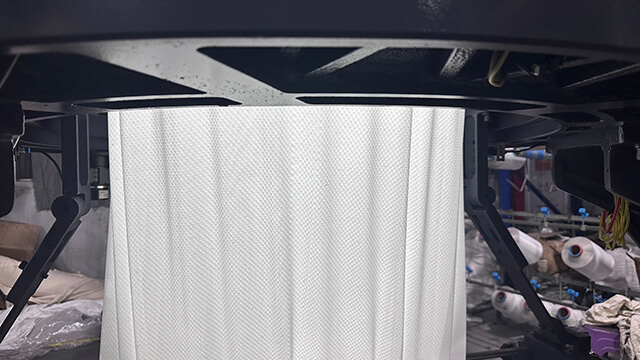

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

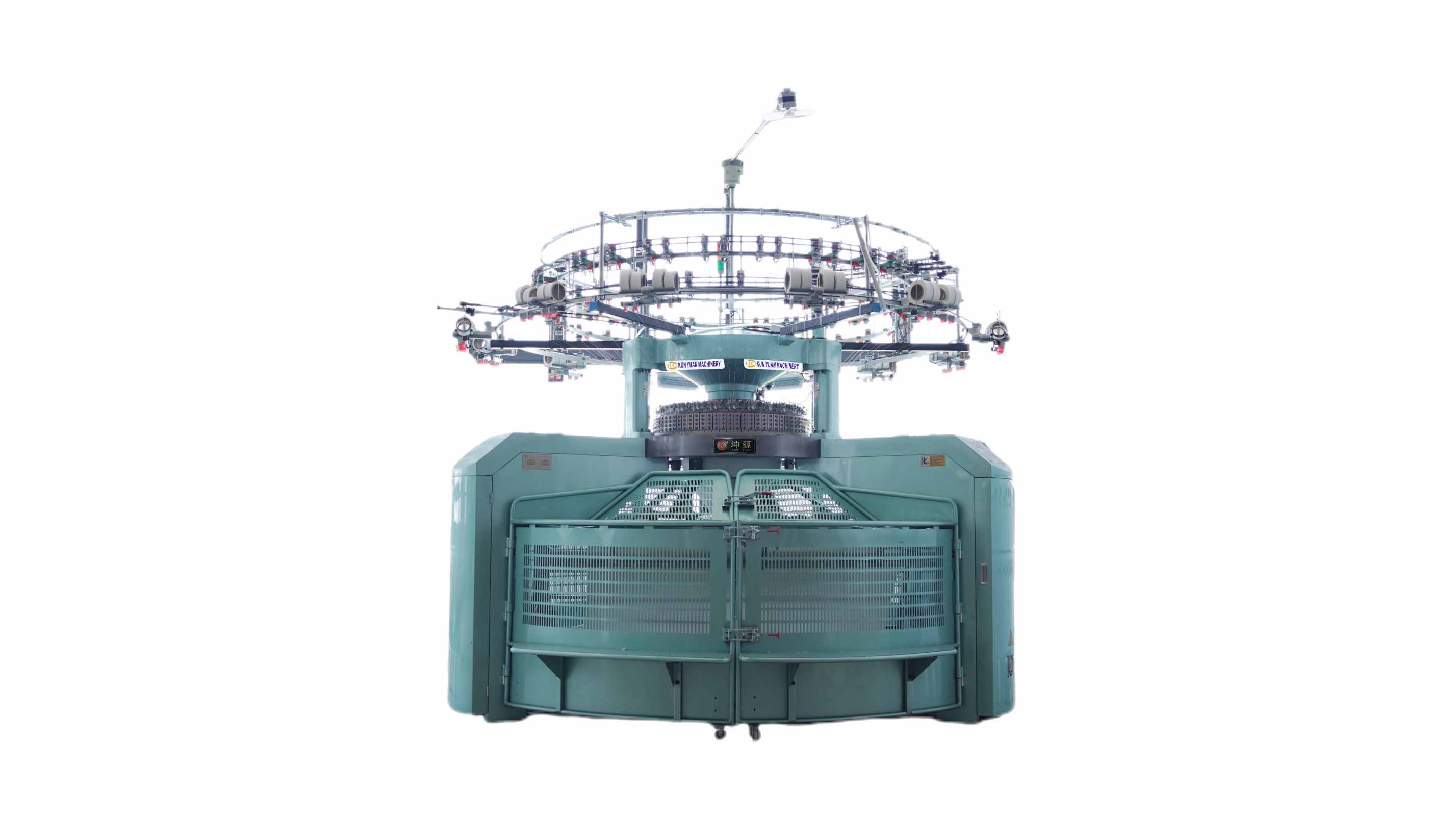

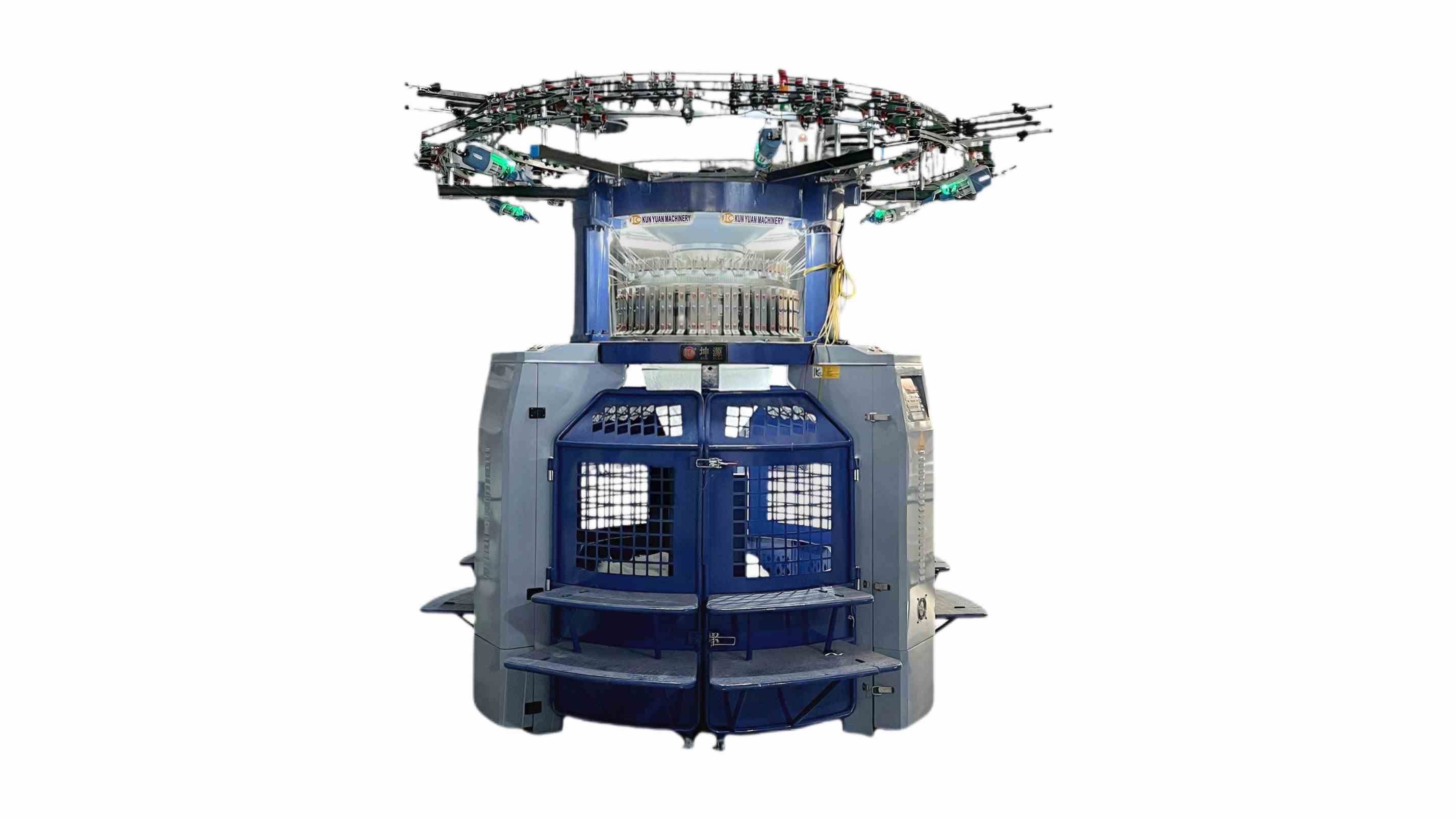

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...