1. Determine the Purpose. 2. Select the Yarn. 3. Choose the Stitch Pattern. 4. Consider the Fit. 5. Pay Attention to Neckline and Sleeves. 6. Experiment with Colors. 7. Quality and Durability. 8. Take Care Instructions into Account. Conclusion....

Introduction. 1. Seamless Construction. 2. Customization and Unique Designs. 3. Efficiency and Speed. 4. Versatility in Material Choices. 5. Sustainable Manufacturing. 6. Comfort and Fit. 7. Cost-Effectiveness. 8. Increasing Accessibility. Conclusion....

1. Versatility in Design. 2. Enhanced Comfort and Fit. 3. Reduced Production Time. 4. Cost-Effective Manufacturing. 5. Seamless Integration of Features. 6. Environmentally Friendly Production. 7. Diverse Yarn Compatibility. 8. Quality Control and Consistency. Conclusion....

1. Read the Care Instructions. 2. Hand Wash or Use a Delicate Cycle. 3. Use Cold Water. 4. Dry Flat. 5. Avoid Direct Sunlight and Heat. 6. Never Use an Iron. 7. Store Properly. 8. Gently Remove Pills. Conclusion....

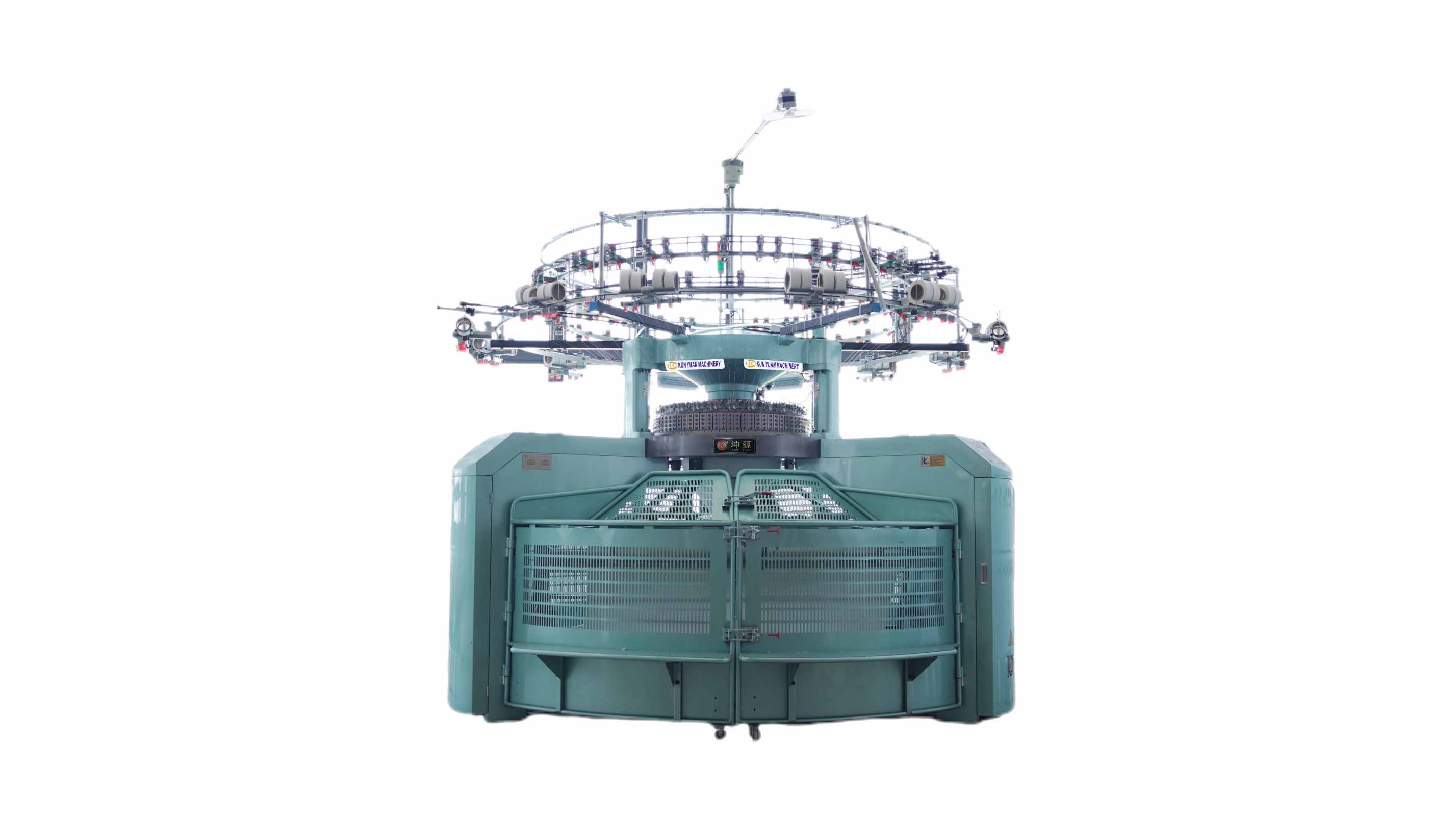

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

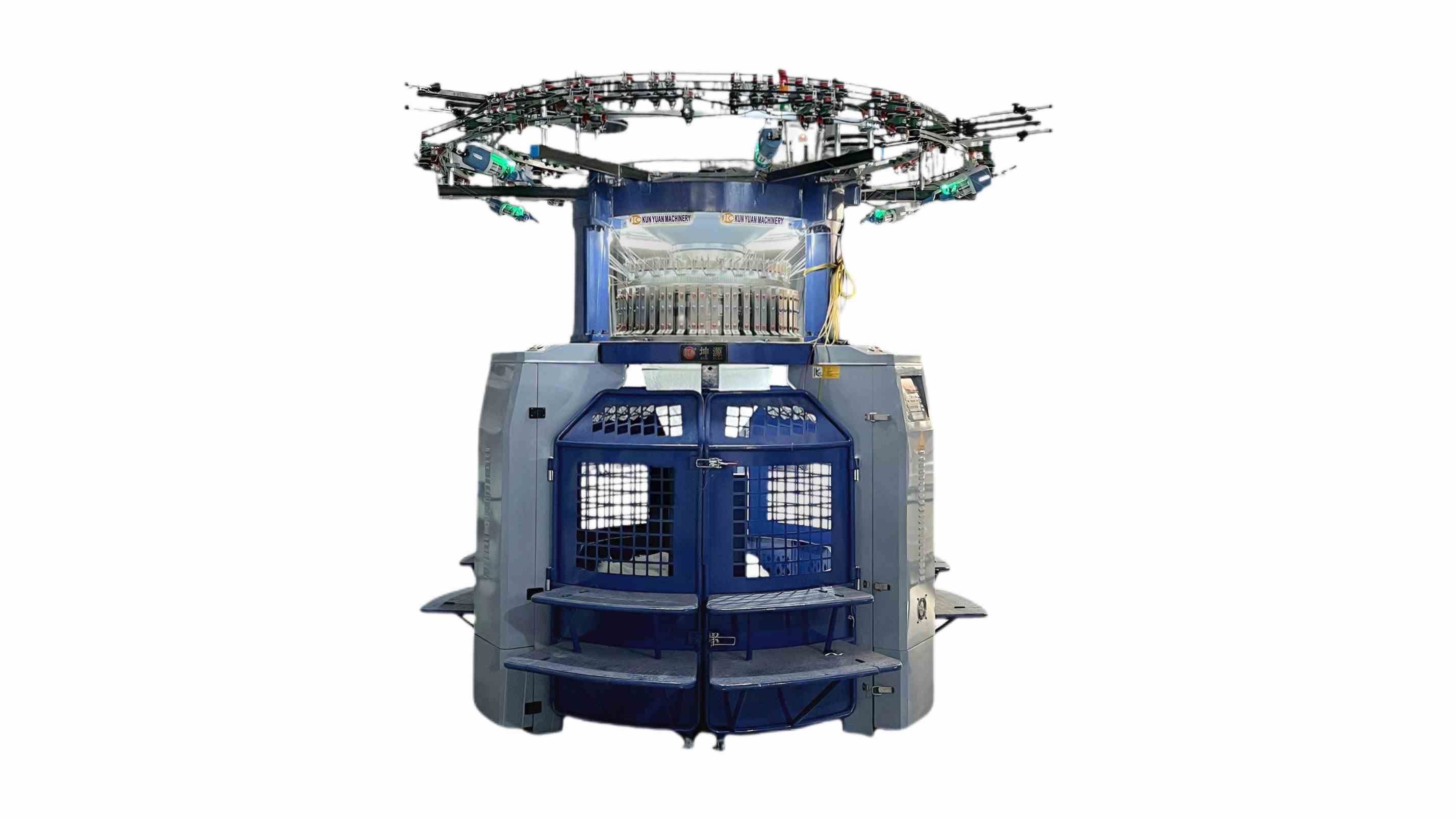

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for pr...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...