Introduction. Advantages of Automatic Circular Knitting Machine. Production Process of Automatic Circular Knitting Machine. Conclusion....

Early Origins and Conceptualization. Emergence of Computerized Control Systems. Advancements in Yarn Feeding Mechanisms. Integration of Seamless Fabric Inspection. Incorporation of...

Increased Productivity. Versatile Design Options. Cost-Effective Production. Enhanced Quality and Consistency. Adaptability to Various Yarns. Integrated Technology and Automation. ...

1. Electronic Jacquard System. 2. Yarn Feeding Mechanism. 3. Automatic Color Changing. 4. Multiple Knitting Heads. 5. Automated Lubrication System. 6. Digital Control Panel. 7. Aut...

1. Introduction. 2. Increased Efficiency. 3. Versatility in Design. 4. Enhanced Control and Precision. 5. Improved Ergonomics. 6. Cost-Effectiveness. 7. Sustainable Production. 8. ...

Advantage 1: Versatility. Advantage 2: High Productivity. Advantage 3: Quality Fabric Output. Advantage 4: Cost-Effectiveness. Production Process Overview. Step 1: Yarn Feeding. St...

Early Manual Circular Knitting Machines. Introduction of Semi-Automatic Machines. Transition to Fully Automatic Machines. Incorporation of Computerized Systems. Advancements in Bod...

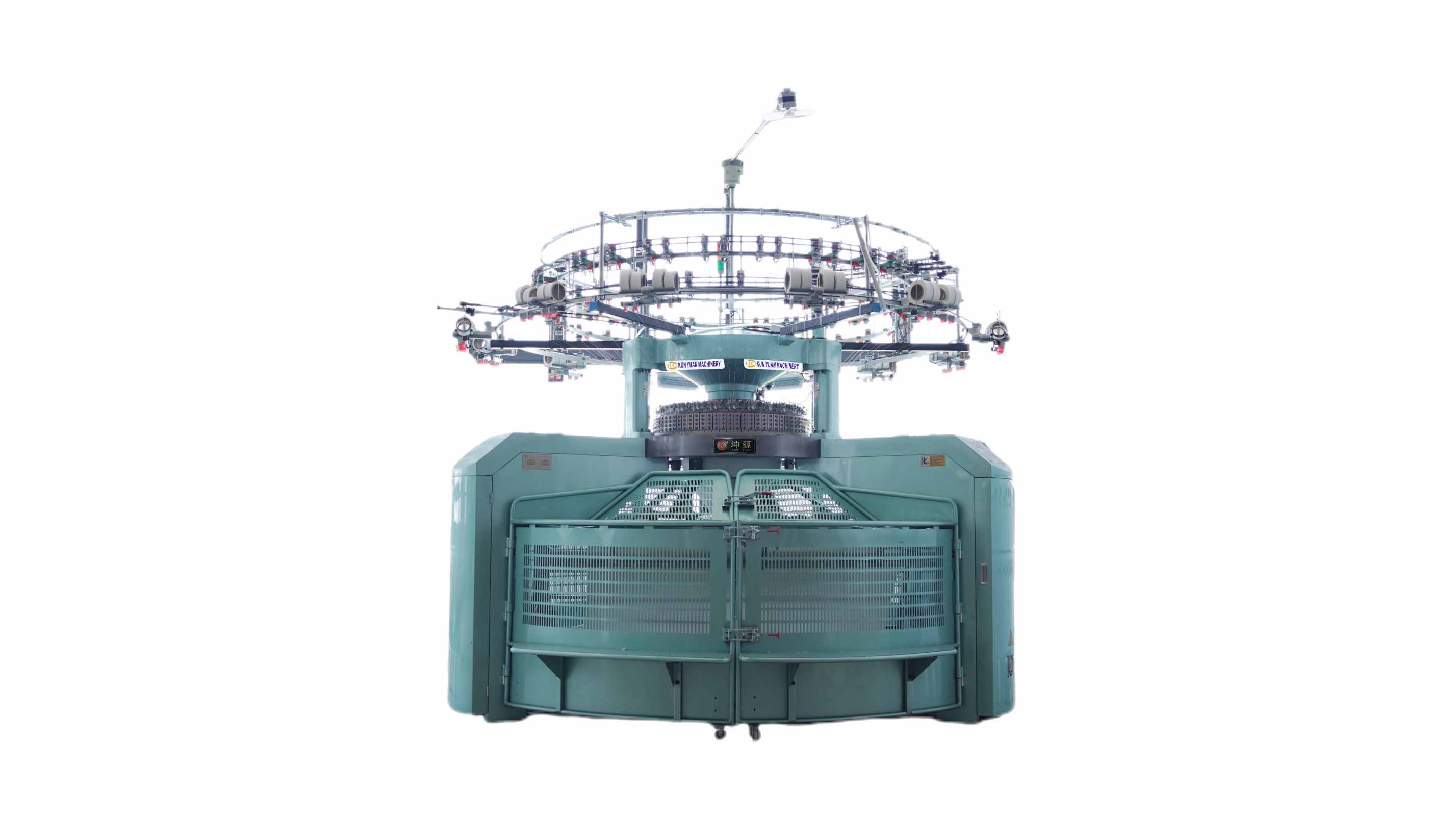

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate an...

1. Fabric Image Description The 32-inch, 22-gauge knitting machine is a common specification used to produce sweatshirt fabrics. 96F usually refers to the yarn count or fineness, indicating the y...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balan...

Yes, knitting machines are widely used in the textile industry for mass production of knitted fabrics and garments. They offer significant time and cost savings compared to manual knitt...

The cost of knitting machines can vary significantly depending on the brand, model, and features. Entry-level machines for hobbyists can range from $100 to $500, while industrial-grade ...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...