The client had been facing increasing demand for high-quality terry fabrics, which their existing machines were unable to meet efficiently. Their limitations in design flexibility,...

The client is a well-established textile producer specializing in high-quality terry fabrics used across various industries. With demand steadily increasing, they recognized the im...

Introduction: Morocco has emerged as a significant player in the global textile and apparel industry. As the country continues to expand its manufacturing capabilities, it is cr...

Our company recently had the opportunity to work with a prominent textile manufacturer in Brazil, helping them upgrade their production capabilities with our advanced High Pile Jac...

Case Study: Our client, a leading textile manufacturer based in Morocco, was seeking to upgrade their manufacturing capabilities and improve the production quality of high pile ...

Introduction:In this case, we present a successful collaboration with a valued client from Pakistan who sought to enhance their textile production capabilities. Our compan...

we will explore the experience of a Belgian customer who invested in a High Pile Cutting Circular Knitting Machine. The customer, a textile manufacturer specializing in high-qualit...

Introduction. Step 1: Unpacking and Inspection. Step 2: Assembling the Machine. Step 3: Connecting Power and Utilities. Step 4: Adjusting Needle Settings. Step 5: Threading the Yar...

Introduction. 1. Unpacking the Machine. 2. Placement and Leveling. 3. Power Supply. 4. Installing Needles and Yarn Feeders. 5. Lubrication. 6. Testing and Calibration. 7. Safety Me...

Installation Guide for Pailung Circular Knitting Machine. 1. Unpacking and Inspection. 2. Machine Placement. 3. Power Connection. 4. Machine Assembly. 5. Lubrication. 6. Thread Ins...

1. Introduction to Rib Circular Knitting Machines. 2. Enhanced Needle Control System. 3. Variable Gauge Capability. 4. Automated Fabric Feeding and Tension Control. 5. Real-time Mo...

1. Machine Size and Diameter. 2. Gauge and Needle Selection. 3. Jacquard System. 4. Yarn Feeder Options. 5. Machine Speed and Efficiency. 6. Maintenance and Service. 7. Cost and Re...

1. Determine your production requirements. 2. Consider the machine specifications. 3. Evaluate the machine's features. 4. Consider the machine's durability and reliability. 5. Asse...

1. Determine Your Requirements. 2. Research Pailung Circular Knitting Machines. 3. Consider Your Budget. 4. Evaluate After-Sales Support. 5. Seek Expert Advice. 6. Compare Prices a...

1. Determine the Purpose. 2. Select the Yarn. 3. Choose the Stitch Pattern. 4. Consider the Fit. 5. Pay Attention to Neckline and Sleeves. 6. Experiment with Colors. 7. Quality and...

Introduction. 1. Determine Your Production Requirements. 2. Consider Machine Specifications. 3. Assess Machine Brands and Suppliers. 4. Evaluate Machine Features. 5. Consider Ease ...

1. Determine Your Skill Level. 2. Consider Your Budget. 3. Evaluate Machine Specifications. 4. Consider Machine Size and Portability. 5. Research User Reviews and Feedback. 6. Chec...

1. Determine Your Production Requirements. 2. Research Different Models. 3. Consider the Machine Size. 4. Examine the Machine Features. 5. Evaluate the Machine's Durability. 6. Ass...

1. Knitting Capacity. 2. Needle Gauge. 3. Rib Structure. 4. Machine Versatility. 5. Machine Durability. 6. Cost. 7. Technical Support and Training. 8. User Reviews and Recommendati...

1. Determine your production needs. 2. Research different brands and models. 3. Consider machine specifications. 4. Evaluate ease of use. 5. Assess the machine's versatility. 6. Co...

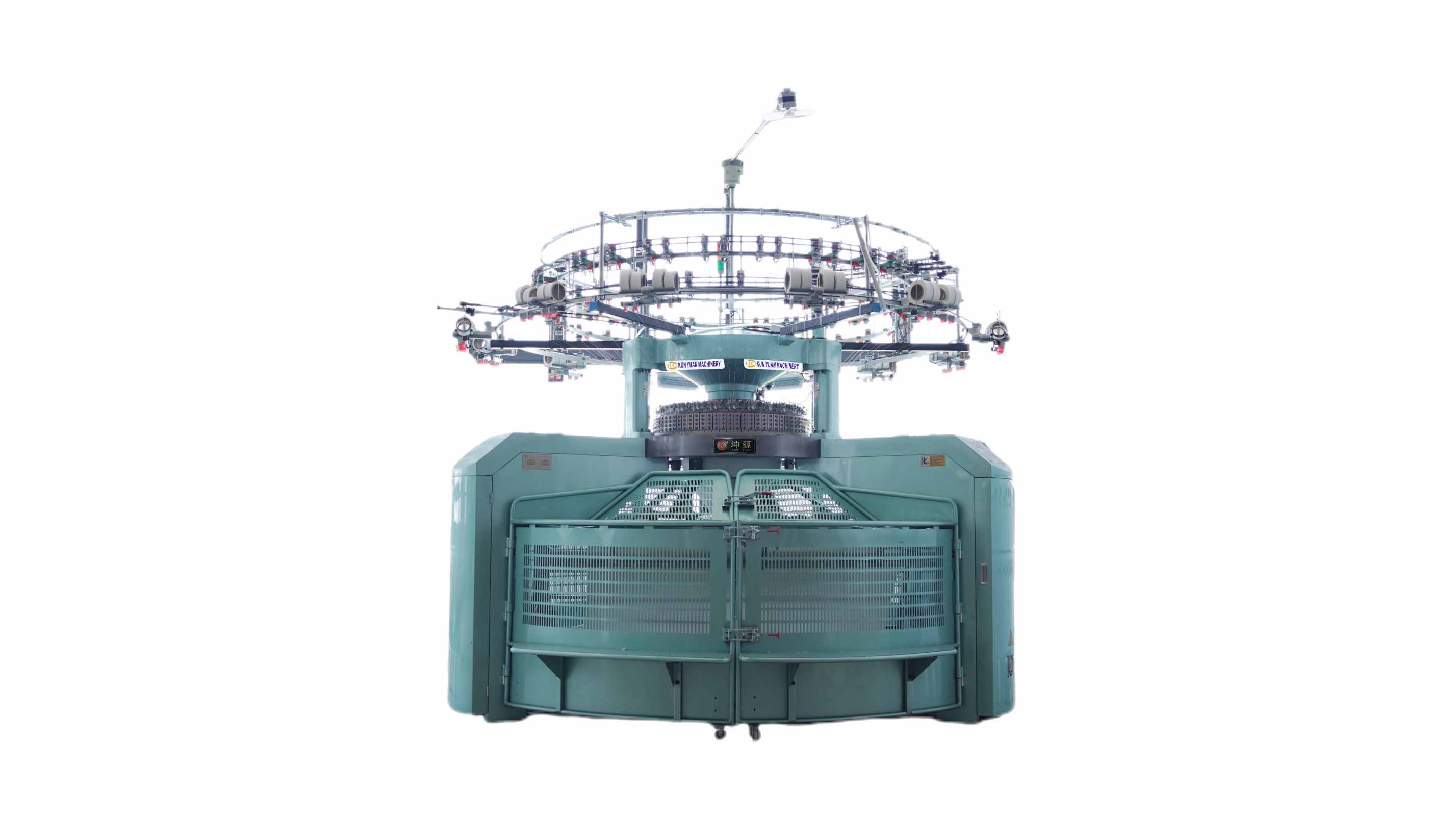

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate an...

1. Fabric Image Description The 32-inch, 22-gauge knitting machine is a common specification used to produce sweatshirt fabrics. 96F usually refers to the yarn count or fineness, indicating the y...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balan...

A knitting machine works by using hooks or needles to form loops of yarn in a specific pattern. The machine can be operated manually or programmed to follow a predetermined design....

There are various types of knitting machines, including flatbed machines, circular machines, and sock machines. Each type has its own advantages and is suitable for different knitting p...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

The 36-Inch 32G 108F Double-Sided Knitting Machine is a state-of-the-art textile machine designed for high-quality, double-sided knitted fabric production. This machine is ideal for p...